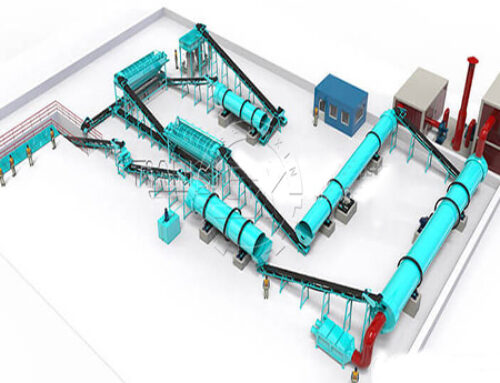

In general, if you want to make organic fertilizer pellets from biomass material, you need to dispose of biomass material with the following steps. Including dewatering, crushing, mixing, granulation and packaging. Through these steps, you can choose to make biomass material into granular fertilizer freely. Then on 6th August 2023, a customer from Russia wanted to know how to make biomass pellets? And what equipment is suitable for producing biomass granules? For this, in order to help him finish biomass pellets manufacturing easier and faster, SX especially designs various fertilizer processing machines for his choice. You must can find the most suitable plan for your biomass granules production.

Which Granulator is Suitable for Biomass Pellets Making?

How to Remove Excessive Water from Your Biomass Material?

What Other Equipment you Need to Make Biomass Granules?

This customer from Russia wanted to buy a biomass pellets plant to process his materials. So we recommended other equipment to help him improve granules quality. Besides the above equipment, there are other machines for your choice:

Grinder for Biomass Material

For biomass material crushing, SXFLF-600 new type vertical crusher is your best choice. It can grind 3-5 tons of biomass materials into finer powder per hour. It is beneficial for subsequent biomass pellets production. Moreover, because this machine is highly adaptable to biomass material with high moisture content. When you process a large amount of biomass material, it is not easy to block and can discharge material smoothly.

Screening Unqualified Pellets

Screening machine can separate qualified biomass granules from the unqualified. So you can return unqualified biomass pellets to reprocess to reduce material waste. If you need a screener with an output of 1-5 t/h, we recommend you buy SXGS-1240 rotary screener.

Packaging Equipment for Biomass Granules

Finally, you need small scale packaging equipment. In this case, we recommend you choose single bucket automatic bagging scale. It can help you pack finished biomass pellets into 25 kg/bag or 50 kg/bag quickly. Then you can sell them to your customers in a targeted way.

Leave A Comment