Feed Pellet Mill for Sale

Besides the powerful granulating machine for making organic fertilizer pellets and compound fertilizer pellets, we also design and make our flat die granulating machine to granulate feed pellets. Feed pellet mill for sale uses crushed corn, soybean meal, rice husk, grass, straw, etc. as raw materials, and then granulate them by the extrusion and press force. You can apply it into your vast farm and pastures, then you can improve the self-sufficiency production chain continuously. And it’s possible that you gain economical profits by making and selling feed pellets.

The following is more information about out feed flat die granulating machines for your reference.

Detailed Designs of Our Feed Pellet Granulation Machine’s Parts

Our flat die feed pellets making machine’s production capacity is up to 0.08-2.5 tons per hour. The shape which is conical, and there are various roller sizes for you to choose. Here we are going to see specific details about its parts’ working way.

The feed inlet is made of stainless steel. The steel does not produce corrosion, pitting, rust or wear. Instead, it can resistant corrosion and enhance the strength.

In the production of grinding disc, it goes through six procedures: forging, turning, drilling, reaming, heat treatment and polishing. Thus, the flat die granulator can discharge faster and has a longer using life. Besides, you can select the hole diameter of the grinding disc according to the different animals you are going to feed. You can also select the diameter according to different output.

We use alloy steel to make pressure rollers. The material is gelled at high temperature between the roller and the grinding disc, and is discharged from the die hole under the roller. This type of pressure roller adopts inclined wheels, which can efficiently reduce resistance and kinetic energy loss.

How To Operate Flat Die Granulation Equipment for Making Feed Pellets?

We have taken vast tests for our machines’ function, life cycle, and anti-wear ability etc. The goal is to make sure that we can provide the best feed granulating machine which has the most stable process procedure after our continuous trying and research. In general, our flat die pellets making equipment’s operation way is like this:

Crusher and mixer help your flat die granulator make much smooth feed pellets.

For making more uniform fertilizer granules, you should ensure no big blocks and other materials in the feed raw materials. Our new type vertical crusher can crush the large caking materials into powdery, which can improve the fees pellets’ smooth degree greatly. Besides, if you want to make your feed pellets have more functions, you can also add functional bacteria etc. To make it play roles well, you can use our disc mixer to mix them. Then you can put materials into the feed port to granulating beautiful feed pellets.

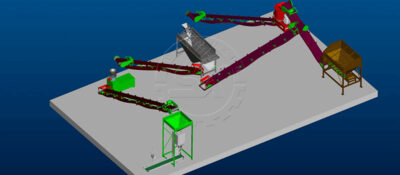

Other auxiliary machines play an important role in the feed pellet mill for sale.

As our flat die granulating machine adopts dry granulation, the materials are dry in and the pellets are also dry out. The moisture is low, which reaches the package standard 20%- 25%. In a scaled production od feed pellet mill for sale, every part has its meanings. Cut one part may not affect the production capacity, but working together will provide you with a much higher efficiency and much more qualified products. In most cases, after the granulation process, you can use rotary screen machine to separate unqualified and qualified pellets away. Then the conveying equipment can send the qualified feed pellets to the automatic package machine, while the unqualified pellets will be return materials to granulate again.

How Do You Choose An Appropriate Location for Feed Pellet Machine for Sale?

Flat fie granulating equipment’s capacity is up to 0.08-2.5 tons per hour. It is suitable for small scale production. So whether you buy the single flat die granulators, or buy the complete feed pellets making production line, it will occupy less land than other granulation production lines. As you don’t have the limits of a large plant area, there will be a freedom for you to set up your plant.

Besides, you can also locate your fees pellets granulating machine where is not far away from the farm. In this way, you will have two obvious advantages. On the one hand, it is easy for your to get mass suitable raw materials for feed. On the other hand, you can sell your high quality feed pellets to farms easily, who will always be the customer of feed pellets.

Your Budget for Purchasing A Feed Granules Making Machine

How much is your budget for one set of feed granules making machine? You may have compared different factories’ flat die granulation prices on all shopping websites. But that’s not enough. The price of one set flat die granultor in our factory is $2800-8100. In other factories, whose production capacity can reach our level, but the price is much more expensive, they sell at least $5000. Some sell for at least $3500 around. Some flat die granulating machines’ prices are cheaper, but the production capacity hasn’t achieved our level. 300-500 kg/h alfalfa flat die granulator sell $2900-7500. So if you aim to have a feed pellets mill which has excellent performance, it would be much better you chose our products rather than others.

You may be a customer in Kenya, or South Africa, Pakistan, USA, or Canada etc., it doesn’t matter that you choose our SX feed pellets granulation machines. We have rich experiences of exporting our machines overseas. And we also import advanced machine parts from abroad. It’s easy to handle your importing problems for us. Believe us, your purchase of SX feed flat die granulator is deserved.