Zeolite Pellets Granulating Machine for Sale

Do you want to make more profits from zeolite recycling? Are you looking for a project for making zeolite rocks into high quality pellets? Take action and turn zeolite rocks into granules! In this process, it is necessary to choose a suitable zeolite pellets granulating machine. In order to fully meet your requirements, YSX not only design various zeolite pellets making machines for your choice, but also setup different zeolite granulation lines to help you finish zeolite pellets smoothly. Are they affordable for you? Of course, as a leading fertilizer equipment company, we will offer you zeolite granulation machines and business plans at a favourable price!

What equipment can you use to process zeolite more suitable for granulation?

Usually, it is not advisable to process zeolite rocks with the granulator directly. So you need to dispose of zeolite rocks in advance. There are two machines as follows:

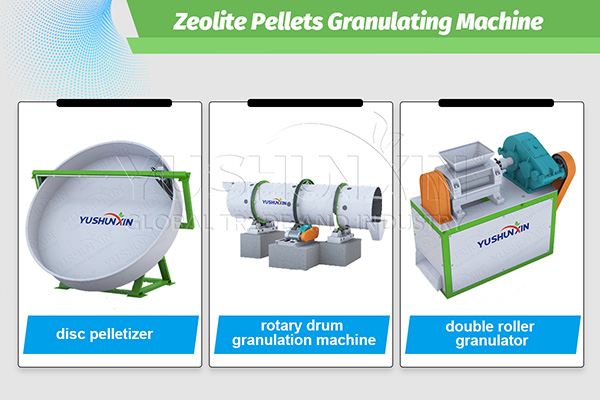

Top 3 zeolite pellets granulation machines for your choice

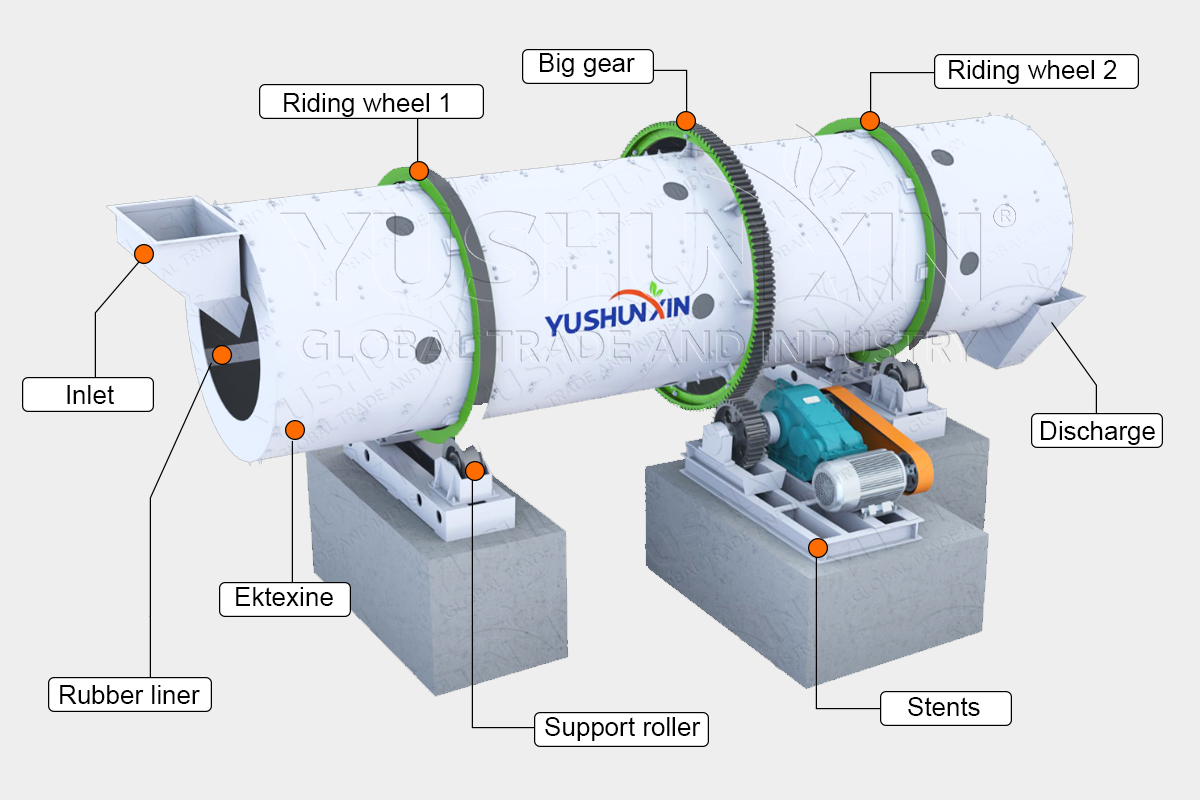

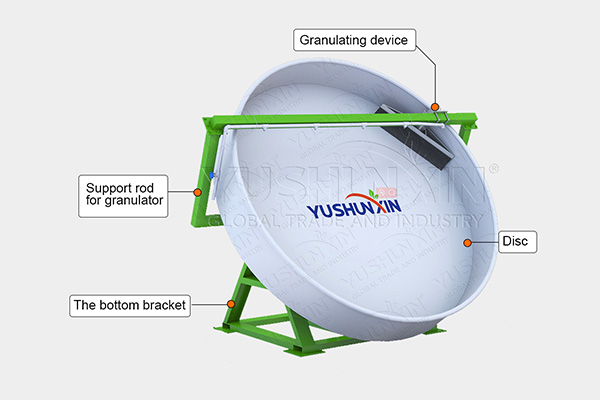

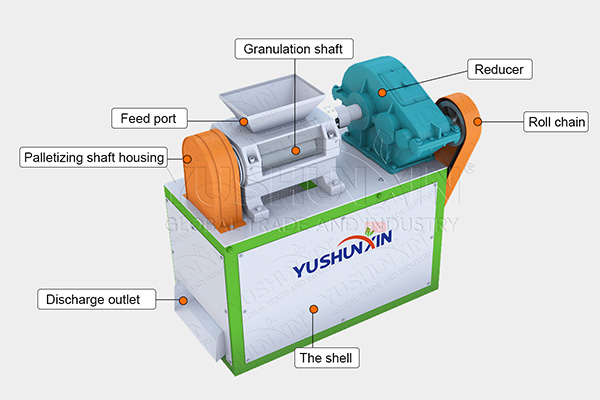

As a professional fertilizer equipment supplier, we can provide you with various mineral pellets granulation machines for zeolite processing. Among them, there are 3 types of zeolite granules pelletizers that are popular with granular zeolite manufacturers. They have different features and are suitable for different occasions, you can choose the right one according to your needs.

What can you do to further improve the quality of zeolite pellets?

Is the granulator the end point of zeolite pellets production? The answer is no. After granulation, you can further improve the quality of zeolite pellets by the following steps:

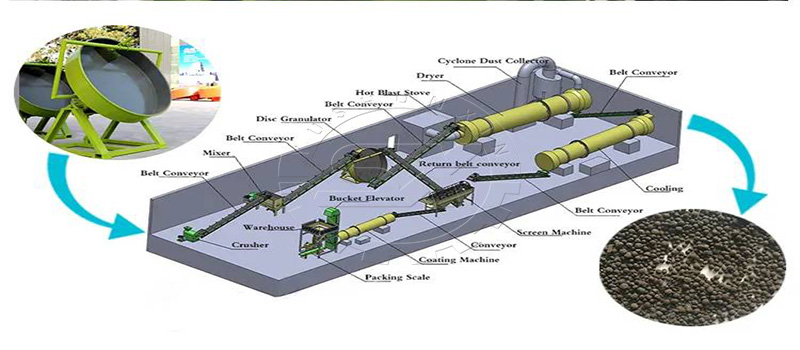

What is the layout of making zeolite pellets?

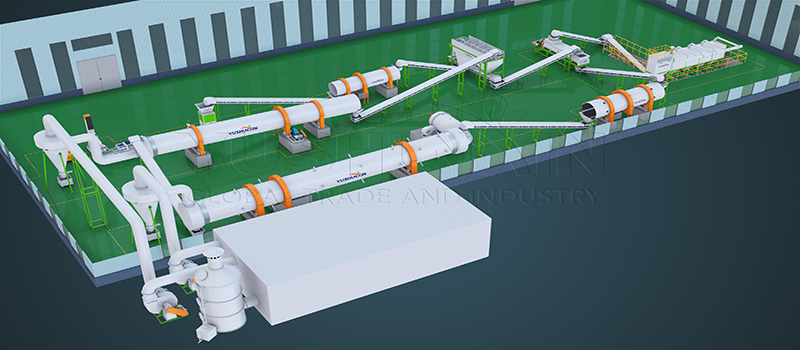

If you want to make large scale zeolite pellets, you can set up a zeolite pellets production line. This whole zeolite pellets plant can help you produce zeolite granules conveniently and increase the quality of zeolite granules.

What is the cost of your zeolite pellets granulation lines?

The price usually plays an important role in zeolite pellets granulation line. Then in items of cost, our zeolite granulation plant can be divided into three parts:

$ 102,311 zeolite granulation line

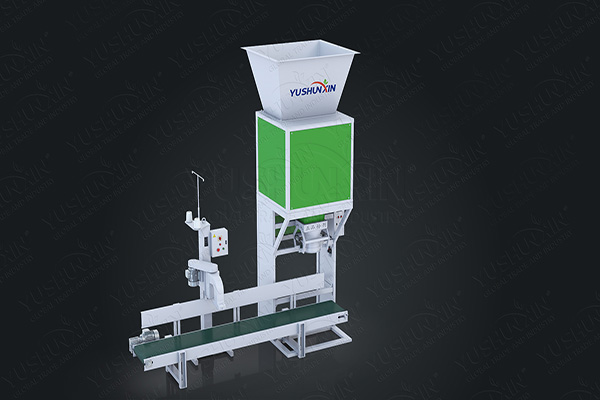

If your budget for granular zeolite manufacturing is lower than $ 102,311, double roller granulator is the optimum option for you. And combing it with small feeder, crusher, mixer, screener and bagging equipment, you can setup a zeolite pellets granulation line with a low investment.

$ 134,709-$ 213,310 zeolite pellets making line

But provided you have prepared $ 134,709-$ 213,310 for turning zeolite into granules, we recommend you buy disc granulation line. It can improve the quality of your zeolite pellets in appearance and hardness.

$ 213,310-$ 500,000 zeolite particles production line

For those who plan to invest $ 213,310-$ 500,000 in zeolite particles production line, you can choose rotary drum pellet making line. It is the best choice to process a large amount of zeolite into pellets in a short time.

Economic Values by Using Our Zeolite Granules Making Machine

Industry market has a large demand for zeolite pellets making machine

Zeolite has the properties of adsorption, ion exchange, catalysis, acid resistance and heat resistance, so it is widely used as adsorbent, ion exchanger and catalyst. Besides, it can also be used in drying, purification of gas and sewage treatment. Thus, industry market has a large demand for zeolite pellets’ production. By using our granulating machine, you can make zeolite pellets with these usages for sale.

Agriculture has a large demand for zeolite pellets granulating machine

Zeolites also have “nutritive” value. Generally, adding 5% zeolite powder in the feed can accelerate the growth of poultry and livestock. What’s more, we can also granulate zeolite pellet as a soil conditioner in agriculture. It can keep land’s fertilizer and water. Besides, it will also prevent pests and diseases significantly. Therefore, with such a large demand of zeolite pellets, our granulating machine will play an important role for gaining economic benefits.

Formula for Granulation Machine Making Zeolite Granule in Raising Pigs

Granulation machine can makes zeolite pellets for raising pigs according to formula. Through scientific studies and practices, containing 50% calcium formate, 8% formic acid and 42% natural clinoptilolite of feed addictive will helpful to the pigs’ growth and development:

Therefore, during the zeolite pellets’ production procedure, we can batch the important raw material: zeolite with other material at a certain proportion to improve the zeolite pellets’ function further.

Besides, more formulas for zeolite pellets’ granulation can be used and made according to the type, purity, geographical source, physical and chemical properties of zeolite, the proportion in feed, and the feed and environmental conditions required. Therefore, you can have much more chances and benefits in granulating zeolite pellets for sale.