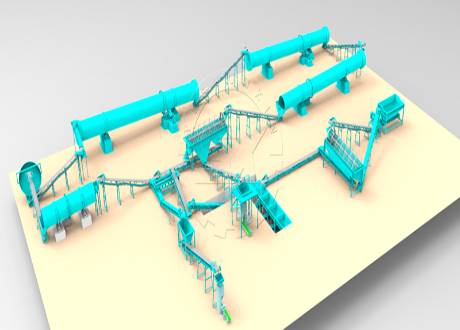

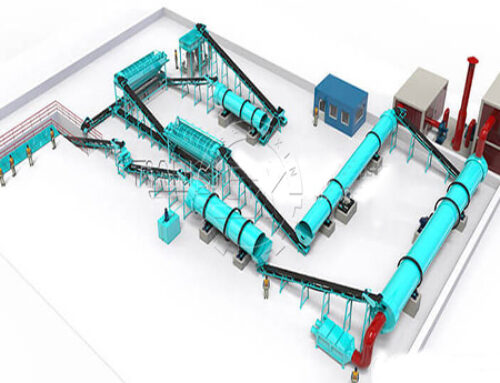

For those who want to make more profits from limestone rocks, the best choice is prepare limestone rocks into granules. And for small-medium scale limestone granules manufacturing, two-in-one disc pelletizer and drum granulator production line is an excellent choice. It can dispose of the large amount of limestone rocks in your factory. In addition, the produced limestone pellets have a higher hardness, which makes fertilizer more convenient to transport, store and use.

And we have some successful cases, for example, on 24th April 2023, a customer from Australia inquired about 10t/h limestone granulation process plant. Finally, after discussing the details, we recommended him the above production line. The following are the details in this case:

Who Need the 10 T/H Two-in-one Disc pelletizer and Drum Granulator Production Line?

Customer from Australia asked us “ Why does 10 t/h disc pelletizer and drum granulation manufacturing line suitable for me? ”. We advised him to consider from three aspects: capacity, final fertilizer products and cost.

Capacity

If you make limestone granules making line work for 10 tons per hour, you can only use rotary drum granulator to produce fertilizer. Because this machine’s capacity is about 3-30 tons per hour. But if you want to make pellets are not only suitable in output, but also in the final quality, two-in-one disc pelletizer and drum granulator production line is an excellent choice. In general, disc pelletizer’s production capacity is 1-6t/h. Although this machine’s capacity can not suitable for 10t/h granules production, drum granulation machine plus disc pelletizer can not only produce 10t/h limestone granules, but also reducing the return rate greatly after two times of granulation.

Final Fertilizer Products

Looking at the final fertilizer granules is an effective way to know is the two-in-one disc pelletizer and drum granulator manufacturing line right for you. In genaral, this production system can meet your requirements of making 3-6mm limestone granules and its granulation rate can reach 97%. In addition, the hardness of its granules will be better than only drum granulator producing. That is , the final fertilizer has a lower possibility of pulverization and is easier to transport, store and use.

Cost

During purchasing production Line for limestone pellets making, cost is an item you must focus on. For a complete 10t/h two-in-one disc pelletizer and drum granulator fertilizer making system, you need to prepare $213,310-$300,000 (reference price). But the price will change with the equipment configure, number, and even time. If you need a precision quotation, please contact us immediately.

How to Reduce the Dust Pollution in the 10T/H Limestone Granulation Process Plant?

When Australian client produced limestone granules a long time ago, there are some dust pollution during the process of making fertilizer. So he wanted to have some solutions to solve this problem. Hence, we recommended him to configure the dust collector, dust fall room and dust cover.

Buying Professional Dust Collector

We can provide you with cyclone dust collector, water curtain dust collector and bag filter dust collector. They are commonly used to collect dust caused by fan in the drying and cooling process of limestone granules preparation.

Building Dust Fall Room

Besides professional dust collectors, you also can filter exhaust gas of drying by building a dust fall room. There are a number of vertical baffles in the dust fall room. When the gas flows through, it will change direction and reduce speed, and the contained dust particles will collide with the baffle and fall.

Adding Dust Cover

But how to prevent dust pollution in other processes of 10t/h limestone pellets manufacturing? You can add dust cover to large scale limestone fertilizer equipment. For example, installing dust covers on rotary screener, belt conveyors, etc.

Leave A Comment