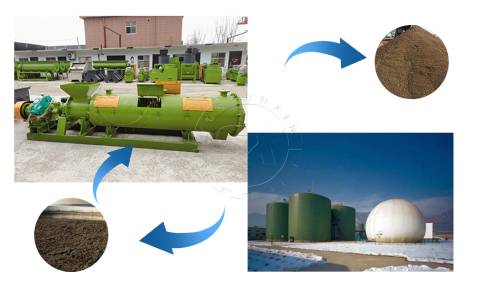

Biogas residue refers to the solid matter formed by biogas fermentation of livestock and poultry manure etc. It is much suitable for making fertilizer pellets by our granulating machine. On the one hand, it is rich in organic matter, humic acid, micronutrient elements, various amino acids, and beneficial microorganisms etc., which can play a very good role in improving soil.

Here are more in formation about our granulating machines in making biogas residue pellets for your reference.

Recommending Granulation Machine for Making Biogas Residues

As the biogas residue mainly refers to the manure, we will recommend the new type organic fertilizer granulation machine to you. A new type organic fertilizer granulator machine (stirring teeth granulator) is a fertilizer production machine. In the making of a new type granulator organic fertilizer, our factory adopts wet granulation. And it’s working procedure is like this:

Product Quality of the Biogas Residue Granules Made by Our Machines

20% Moisture

20% Moisture

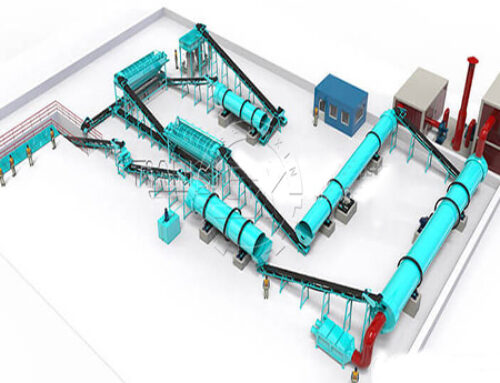

Because our new type organic fertilizer granulating machine adopts wet technology, it usually need to go through the drying and cooling part in a complete production line. Our drum drying machine will at the temperature of more than 300℃ with the support of the natural gas burner and hot blast furnace. While the drum cooling machine extra the moisture under normal temperature, and the wind brought by the fan. Therefore, the formed biogas residue pellets’ moisture is about 20%-30%, which can send to package for sale.

3-10 mm Particle Size

3-10 mm Particle Size

Our granulating machine can turn the biogas residue into 3-10 mm fertilizer pellets. They usually with high hardness, which strength is up to 20-25N. Besides, the biogas residue pellets also have high organic content. We can keep the organic content to the degree of 100%.

Production Capacity

Production Capacity

New type organic fertilizer granulation machine is especially suitable to the large scale fertilizer production. Small scale of new type fertilizer machine has the capacity of 1-2.5 tph, and large scale production capacity of the granulating machine is up to 4-8 tph.

Leave A Comment