Compost Granulating Machine

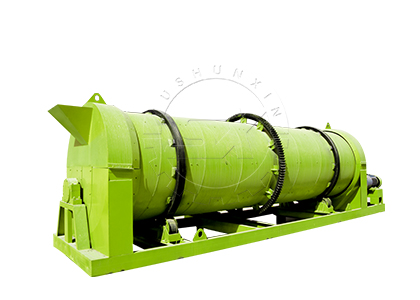

In the whole fertilizer production line, ferment and compost the raw materials of fertilizer is one important part. And these two procedures are next to each other. It can be said that raw materials are all fermented before granulation. The compost granulating machine is mainly used in the organic fertilizer’s production. Significantly, in our factory, new type organic fertilizer granulator, rotary drum churning pelletizer, rotary drum granulator, disc granulator making machine and flat die pellet making machine are all appropriate compost granulating machines.

Here we are going to get familiar with them from their benefits, working technology, commercial models, a complete production line’s working way and the advice for our compost granulation equipment’s layout. You can take if for your reference.

Fermented Raw Material’s Benefits for the Granulation Machines’ Processing

What makes the compost part plays an important role for fertilizer pellets’ granulation? And why do you use compost granulation machine? Here are the main reasons.

How To Select A Suitable Compost Granulating Machine for Yourself?

When raw materials’ moisture is 50%-60%, the raw materials’ fermentation and compost is finished. And then they can wait for fertilizer pellets’ granulation. You can also choose your compost granulating machine by this standard. Primarily, Our granulation machines’ granulation methods have two categories, wet granulation and dry granulation.

New type organic fertilizer granulator, rotary drum churning pelletizer, rotary drum granulator, disc granulator making machine all use wet granulation. The increase in moisture can make powdery and particles coalesce subsequently. They have their own requirements to moisture. Here we can see how our new type organic fertilizer granulator works.

Wet granulation of new type organic fertilizer requires granules moisture to be 30%-40%. When it works, you put adhesive into the raw materials. Then the granules will coalesce by the function of the adhesive. Then under the function of stirring tooth, the pellets’ hardness will improve greatly. The finished products by the new technology organic fertilizer plant granulation have the advantage of high quality, beautiful shape, strong wear resistance, high hardness.

Flat die granulator equipment extrudes pellets from the die hole under the extrusion of the pressure roller. You can add various additives into the pellets’ processing. The materials are dry to put in and the dry products get out from the outlet. They are convenient for sealed storage later. The natural temperature is up to 70-80 degrees, which can kill pathogenic microorganisms and parasites easily, and ensure organic matter content. Similarly, the low moisture pellets are easy for storage. They can keep for a long time in the water, which improves the materials’ utilization greatly.

Hot Products: New Type Organic Fertilizer Granulator Machine for Making Compost Pellets

Among these compost granulating machines, we would like to recommend new type organic fertilizer compost granulator to you. With this granulator in your fertilizer plant, you can make different kinds of fermented organic matter into granulates. To make quality organic fertilizer pellets, we adopt new technology in organic fertilizer production. By this technology, the pellets are usually ball-shaped and the organic content can up to 100%.

You can make desired granules’ size by our new type compost granulating machine.

It is easy for you to make expected pellets size by the new type organic fertilizer pelletizer. The pellets’ diameters are usually 3-10 mm. There are two ways for you to adjust the diameters of the pellets. On the one hand, you can control the material mixing amount. The material mixing amount is much lower, the granules are much smaller. On the other hand, you can adjust the rotating speed of the main axle. the main axle rotating speed is much higher, the granules are much smaller.

Different models of new type organic fertilizer granulation machines for you to pick.

Our factory mainly has five models of this organic fertilizer granulator type, SXJZ-600, SXJZ-800, SXJZ-1000, SXJZ-1200 and SXJZ-1500. Their production capacity is 1-8 tons per hour. Our company integrates Simens, Schneider, ABB and other excellent accessories to improve machines’ functions and performances. The period of use can more than 8 years under your normal operation.

You can also visit our factory in Xingyang, Henan to have a look about how our new type organic fertilizer granulation machine and other compost granulation equipment work. We will give you the best guidance and the most considerate service during you visit. You can realize our factory’s power more truly.

A Complete Compost Chicken Manure Fertilizer Production Line

Besides ensure every machine part is normal, workers, raw materials and machines etc. are ready for the working, the preparations about other machines can also help improve the efficiency of compost granulating machine.

Crusher help compost granulator make more smooth pellets.

For making more uniform fertilizer granules, you should ensure no big blocks and other materials in the raw materials. Our new type vertical crusher can crush the large caking materials into powdery, which can improve the fertilizer pellets’ smooth degree greatly.

Mixer help your machine makes functional fertilizer pellets.

If you want to make your feed pellets have more functions, you can also add functional bacteria etc. To make it play roles well, you can use our disc mixer to mix them.

After these preparations, you can put materials into the feed port to granulating beautiful pellets. These machines will help to expand the advantages of composting raw materials, and then make your granulation procedure is much more efficient.