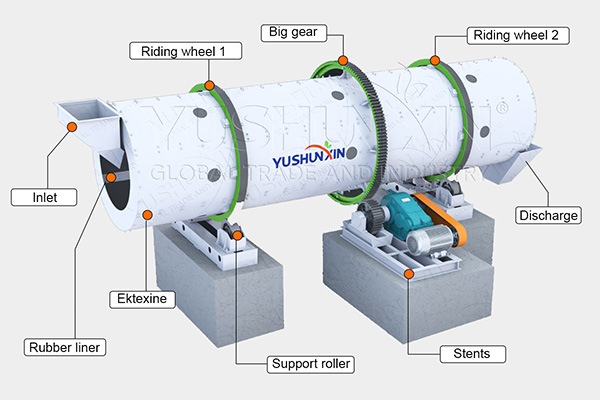

Rotary Drum Granulator

Rotary drum granulator is a molding machine that can make raw materials to a specific pellet shape. It is one of the key granulating machines manufactured by YUSUNXIN, which is a crucial equipment in the compound pellet fertilizer production line. And it adopts the way of wet type granulation that means you should make your raw materials contains 25% to 30% moisture. Among Shunxin all the kinds of granulating equipment, the rotary drum pellet making machine has the largest capacity that can reach 30 tons per hour. Therefore, SX rotary drum granule processing machine is the first choice to the pellet fertilizer production manufacturers in domestic and abroad market, especially for large scale granulation manufacturing business plan.

Different raw materials of rotary drum granulation machine

SX rotary pellet fertilizer making machine can produce both compound pellet fertilizer and organic pellet fertilizer. There is no doubt that the two different types of pellet fertilizer need different raw materials. So we will show what raw materials they relatively need as follows. For a compound fertilizer rotary granulator, the raw materials are some base fertilizer powder and semi-finished products of compound fertilizer. To be specific, they are ammonium nitrate, ammonium sulfate, urea, calcium superphosphate, potassium chloride muriate, potassium sulphate and so on. For an organic rotary drum granulating machine, the source of the raw materials is very wide. They could be:

Using these raw materials to make organic pellet fertilizer with SX rotary drum fertilizer making machine, you can earn more profits because these raw materials are and easy to get. What’s more, it is also eco-friendly to process wastes into pellet fertilizer.

What’s the Working Principle of Drum Granulator Machines?

If you know how a rotary granulating machine works, you will have a better understanding of this granulator. The following is the specific working principle of rotary drums.

Above all, due to the continuous input of materials and the continuous rotation of the granulator, mass production can be realized. There is a small amount of returned materials, and the particle size is small in the granulation line. They can re-granulate without much cost.

How to improve the granulation rate of drum pelletizer?

High-quality rotary drums can guarantee a high granulation rate, but you also need to maintain high-quality rotary granulators. If you do a good work to maintain it, you can make use of your rotary drum for a longer time.

How to maintain the rotary drum pelleting machine when it’s not in use?

To make sure the granulator has stable efficiency and longer working life, the cleaning and maintenance is very important when it’s not in us. So how to maintain the machine correctly and economically? As an experienced equipment supplier, we will give you some helpful suggestions.

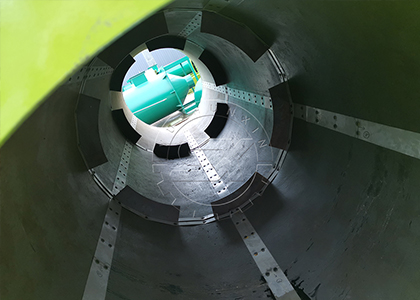

If your fertilizer materials have high stickiness or corrosiveness, they are very easy to stick to the inner wall and even cause damage. To help you clean the sticking fertilizer materials easily, we designed cleaning holes on the drum surface. You can use a hammer to knock the exposed lining wall through the holes. The fertilizer will fall down with the lining wall vibration. And we can also equip the equipment with automatic hammers, that will save you lots of time and energy.

The basis of maintaining fertilizer granulator is to make sure the working environment is clean and dry, without strong acid and corrosive substance. That will greatly reduce the damage from water, dust and corrosion. If the machine can’t work for a long time, you need to oil the important working parts (bearings, motor gearing, etc) regularly to prevent rust.

Before using the granulator, it’s very necessary to check important parts of the machine. Only make sure that all parts are normal can the machine start to work. If there is something wrong before or during working, the operator needs to stop the granulator to find out causes and maintain the machine timely.

By controlling the moisture:

Firstly, you can control the water spray system to control the raw material moisture. If you add less water into the materials, the smaller size granules you will get; instead, if you add more water, the bigger size granules you can get.

By controlling the slope angle:

Secondly, you can regulate the granulator slop angle to regulate the final granules size. Therefore, sharp slope will make smaller size fertilizer; slow slope will make bigger granules.

The Most Appropriate Production Level of Rotary Drum Pelletizer Provided for You

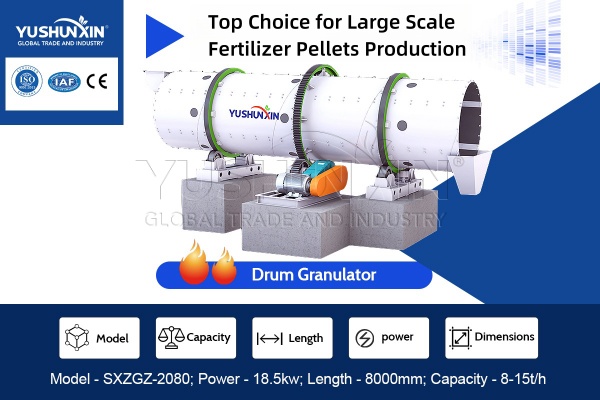

We have developed different drum granulation models to satisfy your production demands. You can buy the most appropriate production level of rotary drum pelletizer in our factory accordingly.

- A small size pelletizing drum can product fertilizer pellets 1-5 tons per hour.

- A medium size machine can produce 5-8 tons per hour.

- And a large scale granulator can make 8-30 tons pellets in one hour.

Whatever pellets’ size you want, we all can make it produced on a large scale.

What is the price of rotary drum pelletizer?

When it comes to price, it is understandable that all the investors want to know. Generally speaking, SX rotating granulator has a reasonable price. It not only has large capacity, but also has wide application. Firstly, you can use our drum pelletizer finish 15-30 t/h granular fertilizer production. Furthermore, it is perfectly for pelletizing both organic fertilizer and compound fertilizer. That is to say, you invest one machine, which can help you to make two types fertilizer. The most important is SX has its own factory and the rotary drum granulator is manufactured by itself. Therefore, the quotation you get is absolutely factory price. If you have interest, please feel free to inquiry us for the latest information.

What is the difference between disc granulation machine and drum pelletizer?

As you know that both the rotating granulator and the disc pellet making machine employ the ways of wet type granulation. However, there is also some difference as follows:

Drum Granulation Fertilizer Production Project for Making Chicken Manure Fertilizer Pellets

Rotary drum granulator machinery is suitable for fermented poultry manure and plant materials. It is mainly used in the granulation of organic fertilizer and compound fertilizer.

We have rich experiences in the whole production line for the rotary drum granulator. And we provide high quality motors and auxiliary equipment like crushers, screens etc. You can start your fertilizer granulation business at a high level quickly by buying our products.

Chicken manure organic fertilizer production line is an important fertilizer granulation line project. If you are going to choose the rotary drum granulator equipment to turn the chicken manure into fertilizer, the powder chicken manure fertilizer process will go through fermentation, crush, screen and packing. Similarly, if you are going to make chicken manure fertilizer granules, the production line includes the procedure of fermentation, crushing, screening, granulator, dryer, cooler, screening and packing.

2 Tips for You to Buy A Drum Granulating Machine Matched with Your Business Scale Perfectly

Here are several tips for your reference to buy a drum granulating machine. We conclude them and extract some tips here for you. You can contact our customer service directly for getting more information and purchasing advice.

To make sure the granulating drum matches your business perfectly, we will recommend the appropriate model for you according to your needs of production capacity and raw materials. Generally, our granulating machine can turn three tons raw material into one tons fertilizer pellets. We can use this note to calculate your production capacity initially.

As for your factory’s layout, we can also help you design the diagram and the production line. There usually need more than 5000 square meters for setting up a whole drum granulation production line. With the design of our experienced engineers, they can make full use of your plant area and design the best factory for you.