NO.1 Rotary Drum Granulation Machine

Rotary drum granulator is the NO.1 fertilizer pelletizer in the first half of 2023. But why so many customer choose this granulator to make pellets?

NO.3 Double Roller Press Granulator

Extrusion granulation is suitable for processing materials with the moisture content of below 10%. It uses dry extrusion method to make compound fertilizer granules. The fertilizer materials will though the gap between the two rollers, which have many semicircular sockets. They will help the materials turn into fertilizer pellets. And because there is nearly no water during the process of granulating by double roller pelletizer. You don’t need to spend money on subsequent drying and cooling. It is also an excellent choice for those whose budget is not enough.

FAQ

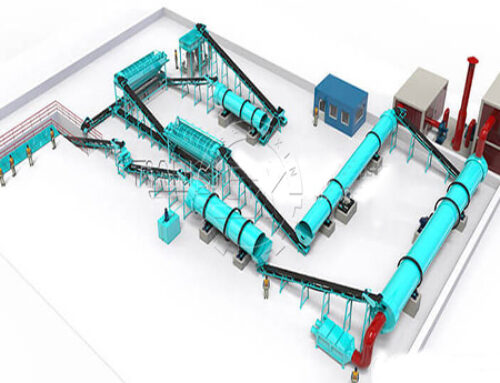

The above is the top four hot sale fertilizer granulating machines of SX fertilizer equipment factory in 2023. There are many other high quality fertilizer processing machines on sale. For example, granulate dryer, limestone pellets production line, zeolite pellets machine and NPK granulator. If you are interested in them, please contact us. We will provide you with high quality fertilizer processing machines at an ideal price!

Leave A Comment