Bio Fertilizer Granulator

We are a professional manufacturer that has rich experience in making and then selling bio fertilizer granulation machines. Bio fertilizer granulator has obviously two reasons that most customers choose our company. On one hand, the bio fertilizer pellets made by our machine have the advantages of cheaper prices and higher organic nutrients and biological bacteria. They have huge economic values. On the other hand, we gain our customers trust and support because of our whole-sale service and strong technology power.

Here is more information about our bio fertilizer granulating equipment for your reference, which includes our bio fertilizer granulation machine types, application and its working principles to illustrate.

Different Production Capacity of Bio Fertilizer Pellets Granulation for Sale

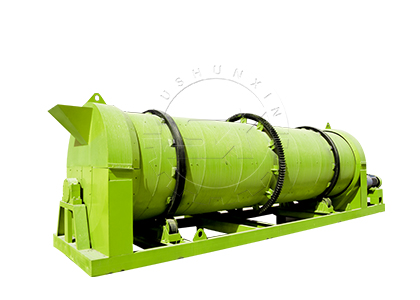

In short, our factory has developed five granulation machinery for bio fertilizer granules: new type organic fertilizer pellet making machine, rotary drum churning pelletizer, rotary drum granulation, pan granulator, and flat die pellet mill. You can choose them according to their production capacity accordingly.

Raw Material for Bio Fertilizer Making Machines

Bio-organic fertilizer refers to fertilizer that composes of specific functional microorganisms and organic materials. Resources are animal and plant residues (such as livestock and poultry manure, crop straw, etc.) mainly. Our bio fertilizer pellet making machine can take a wide range of raw materials into pellets. Our factory has rich experience in turn Livestock and poultry manure such as chicken manure, cattle, sheep and horse manure, rabbit manure etc. into bio fertilizer pellets.

For example, if you are going to take chicken manure as bio fertilizer’ raw material by bio fertilizer rotating drum granulator. The real working and processing procedure is like this. It’s belt and pulley are transmitted to the drive shaft through the reducer. And the split gear installed on the drive shaft meshes with the large ring gear work in opposite directions to convey bio materials. The chicken manure is fed from the feed end and passes through the inside of the cylinder. Through the process of the special structure inside the cylinder, raw material is made into bio granules. Finally, it flows out through the discharge port.

We have been a mature manufacturer in making bio fertilizer granulating equipment after a long time search and practice. And you can trust our ability to make these raw materials into competitive bio fertilizer pellets. If you have interests or questions, please contact our customer service at any time.

New type organic fertilizer pellet making machine, rotary drum churning pelletizer, rotary drum granulation, pan granulator all use wet granulation technology. However, flat die granulator equipment adopt dry granulation during the process.

It extrudes pellets from the die hole under the extrusion of the pressure roller. You can add various additives into the pellets’ processing. The dry materials are put in and the dry products get out from the outlet. The natural temperature is up to 70-80 degrees, which can kill pathogenic microorganisms and parasites easily, and ensure organic matter content. They can keep for a long time in the water, which improves the materials’ utilization greatly.

Working Principle of Bio Fertilizer Granulating Machines

New type organic fertilizer pellet making machine, rotary drum churning pelletizer, rotary drum granulation and pan granulator all adopt the wet granulation. We can take the rotary drum churning pelletizer working way as an example.

Through a certain amount of water or steam, the basic fertilizer is fully chemically reacted after the humidity is added into the cylinder. Under certain liquid phase conditions, the rotation of the cylinder is used to make the material particles generate extrusion force to agglomerate into balls. The wet stirring tooth granulator uses the mechanical stirring force of high-speed rotation and aerodynamic force to granulation continuously. The combination of these two granulation methods makes the granules have a higher spheroidization rate and much more beautiful.

Unlike dry granulation pellets’ 10% moisture, you must make sure raw material moisture is between 20-30% by wet granulation. As a result, you need extra cost to dry and cool the bio fertilizer pellets after granulation to control moisture for the package. In case that high temperature will make the nutrients and microorganism lost, we can help you to control the most appropriate temperature for your plant.

A Full Bio Fertilizer Granulating Production Line’s Design for You

You know it’s time for you to start a full bio fertilizer granulating production line after knowing the comprehensive information about granulator machines for bio fertilizer and careful consideration. And we can provide design and guidance for you. Here is one example to know how the whole bio fertilizer granule machine plant works.There are usually seven steps in rotary drum churning granulation for bio fertilizer.