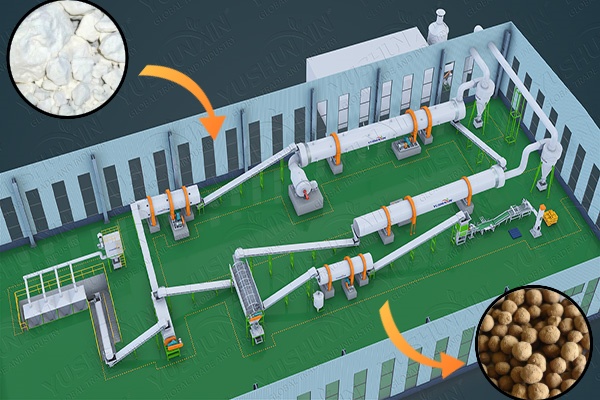

Limestone Pellets Granulating Production Line

Are you finding solutions to limestone disposal? Do you want to know what limestone processing projects are available for you? Do you want to buy quality machines for your limestone pellets granulating production line? You can find answers from SX. SX, as a professional fertilizer equipment factory, has advanced technology and years experience in limestone pellets making machines manufacturing. Besides quality limestone granules equipment, we also can provide you with various projects for limestone processing. In addition, if you have any requirements, you can contact us for customization. We will try our best to help you start the limestone granulation plant smoothly!

2 Projects for making dry and wet limestone pellets

In general, most limestone pellets manufacturers prefer to prepare granules into two forms. Wet and dry. So in order to meet the different requirements of our customers, we especially design wet limestone pellets making line and dry limestone granules production line separately.

How to start a small and large scale limestone pellets granulating production line?

Besides limestone pellets form types, we also can offer you designs according to the capacity of your limestone pellets granulating production line. Whether you plan to produce limestone granules in a small or large scale.

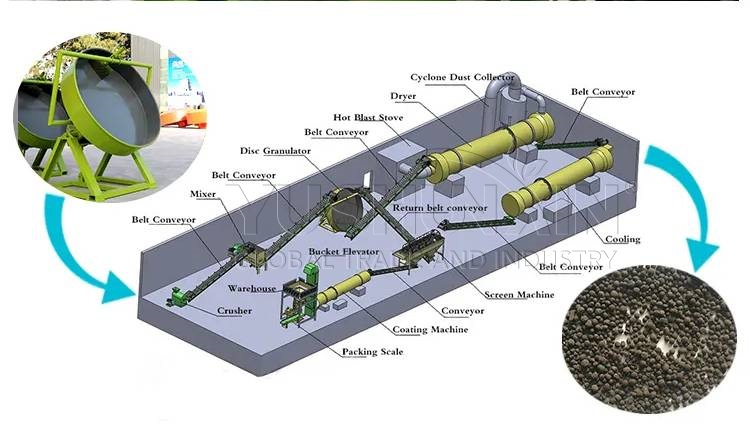

What limestone pellets making machine is needed in disc granulation system

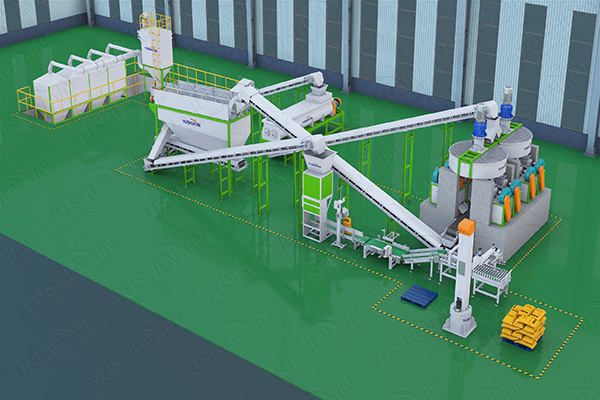

For running disc pan granulation line, you need to buy limestone granules machines of hammer mill, Raymond mill, static batching machine, double shafts horizontal mixer, SXYZ-3600 disc granulator, SXGS-1240 rotary screener, SXHG-1515 rotary dryer, SXLQ-1515 rotary cooler BM1400x4000 coating machine, automatic bagging machine and so on.

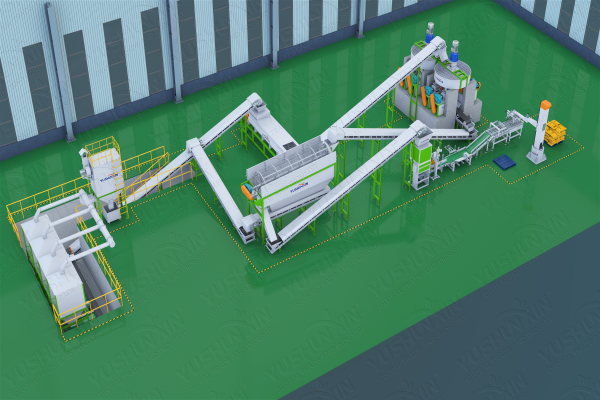

Is there any other system for small limestone pellets manufacturing

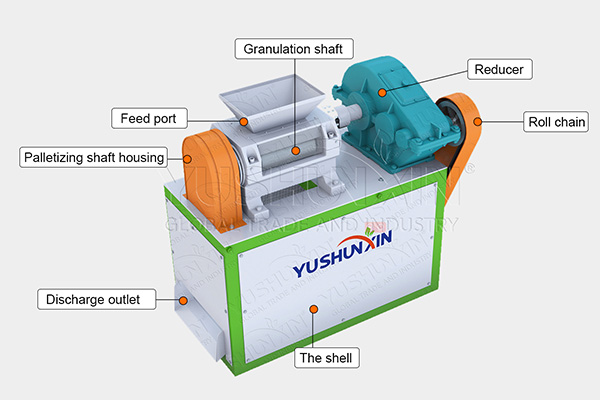

Of course. For making limestone granules in a small scale, you also can choose our double roller dry granulation line. It adopts dry granulation method, which relies on physical force between two rollers to granulate limestone pellets. There is nearly no water involved, so it is dispensable to buy dryer and cooler. In this way, you can spend less and don’t need to prepare a large installation area.

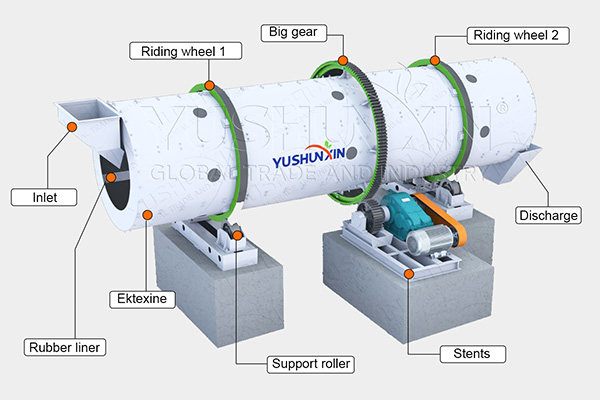

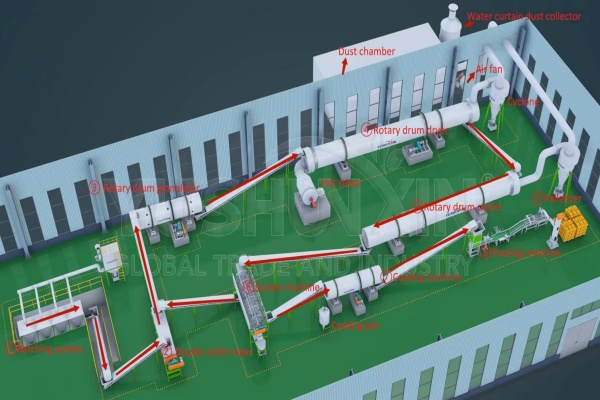

What is the configuration of rotary drum granulation system

For large scale limestone pellets making, you need to purchase equipment with large output. So our rotary drum granulation line usually contains hammer mill, Raymond mill, dynamic batching machine, SXWJ,-1630 horizontal mixer, SXZYZ-2080 rotary drum pellet making machine, SXGS-2080 rotary screener, SXHG-2424 rotary dryer, SXLQ 2424 rotary cooler, BM1600x6000 coating machine, automatic packaging equipment and so on.

What is the cost of limestone pellets granulating production line?

When you plan to setup a limestone pellets production plant, cost is an item you must focus on. Because it is closely related to the choosing of granulation method, equipment configuration, etc, As a professional fertilizer making machine manufacturer, SX especially design different scale limestone pellets making projects according to different budgets. They can fully meet your needs, whether you have a small or large budget for limestone granules making plant setup.

Limestone Resource Saving by the Granules Making Line

Preferred Dry Granulation for Turning Limestone Into Pellets

To turn limestone into pellets, you can use dry granulation method or wet granulation method. They both can granulate pellets efficiently. Many fertilizer manufacturers prefers the dry granulation method to make pellets, and here are the main reasons:

Firstly, the roller compactor adopts dry granulation. Dry granulation is different from wet granulation. There is no need to put adhesive into the materials, or increase the moisture content. It granulates under the normal temperature. The raw materials’ moisture is 5-10%. In this way, there is also no need for drying the formed granules, which cuts a lot of cost in your production. Besides, as the friction coefficient between the materials and the rollers is small, the energy cost is also much lower.

What’s more, this technology reduces the granulation cost compared with other granulators. And the production is relatively easy without adding any additives. It can not only keep the calcium oxide content and activity unchanged after granulating the active lime powder, but also maintain a certain mechanical strength of the active lime, so that the material is fully purpose of use.

Therefore, you can use our double roller granulating machine to make high quality and functional limestone pellets with dry technology. There are different models and types of it in our factory, you can choose the one which is the most suitable to your taste.

A limestone pellet granulation line is a process of convert limestone powder into small pellets. The process involves several steps, including grinding the limestone into a fine powder, mixing it with a blender, and then pressing it into small pellets using a pelletizer.

Overall, the limestone pellet granulation process can be a highly efficient way to produce high-quality pellets, which can apply in different fields.

Where Need A Production Line of Making Limestone Granules?

As we mentioned earlier, limestone is one important material for the production and development, it has wide application in industry, building, food, and agriculture etc. Therefore, our limestone granules production line also has a wide application in these fields to make contributions. Here we take two examples for references.

You can apply the limestone granulation line in the production of glasses-making industry, and iron-making industry. They can take use of the wasted limestone materials to the extreme.

In the fact, the limestone granules production line has a wide application in the agriculture:

First of all, it can granulate the quicklime into Bordeaux mixture, lime-sulfur mixture and other pesticides; secondly, slaked lime pellets made by the whole production line apply into the soil, which can improve the internal composition of the soil, and supplement the calcium in the soil.

Therefore, limestone granules production line has many usages and can create huge economic values for you.