Animal Waste Fertilizer Granulator

Poultry manure is an important raw materials for organic fertilizer production. Our company also realizes its high organic nutrient and huge economic value, and we have developed the whole animal waste fertilizer granulating production line. Animal waste fertilizer granulator has more related information on our website, for example, bio fertilizer pellets granulation machine, chicken manure fertilizer pellets making machine etc.

Here we are going to take the three large scale livestock waste fertilizer granulator, for examples: new type organic fertilizer granulator, rotary drum churning pelletizer and rotary drum granulator. Initially, it’s going to start with the topics of company’s strength, production scales, cost, design and granulation line to help you choose animal waste fertilizer granulator.

Why Do You Choose Our Animal Waste Fertilizer Granulator Factory?

Shunxin manufactures animal manure fertilizer granules machine has advanced technology and unique designs. If you choose our SX waste manure pellets making machine, your poultry manure organic fertilizer has these obvious advantages subsequently:

We apply organic fertilizer into agriculture. Because of the high organic nutrients contained in the manure fertilizer pellets, they can make plants, fruits, and vegetables to grow much more healthier and stronger.

As our machines can make poultry manure into pellets high efficiently, they can disposal the large amount of manure timely. Otherwise, the smell and the floor area it uses will both cause environmental problems later.

Manure organic fertilizer has great advantages in the fertilizer market because of its superlative features, which has high organic nutrient and non-pollution production. More and more agriculture significantly need organic fertilizer to help them to produce green, healthy and high nutrient products, which make manure organic fertilizer much more popular nowadays. You can create immense economic values by using our pellet mills for manure.

Three Types of Granulators for Making Animal Waste Fertilizer Pellets

Ultimately, there are new type organic fertilizer granulator, rotary drum churning pelletizer and rotary drum granulator prepared for you to start making. They have different power consumption, and production capacities. We can make an easy comparison from these aspects for you.

New type organic fertilizer granulator for making animal waste fertilizer.

Scaled new type fertilizer of granulators can make animal manure granules 1-8 tons per hour. Their total power is 37-110 kw accordingly. The pellets’ diameters are usually 3-10 mm. Usually, the granulation rate is above 90%.

It’s easy to find alfalfa as your raw materials for granulation.

Alfalfa pellets are a legume and a green manure. It has much kinds particularly, which you may haven’t noticed. You may find much more in the villages, mountains, furthermore, some farms have scaled alfalfa production. You can build your factory much closer to these places. After you buying our alfalfa pellets granulation equipment, it will cut extra transportation during granulation process.

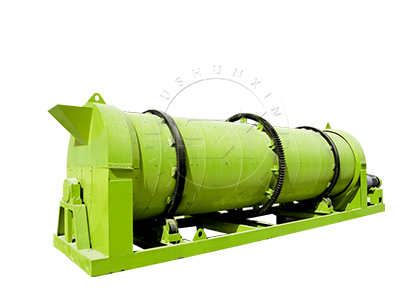

Rotary drum granulator in making animal manure fertilizer pellets.

This type of manure granulating machines is much suitable to the large scale fertilizer production. It can granulate manure pellets 1-30 tons per hour. The power consumption is 5.5-37 kw/h. And this machine granulation rate is high up to 70%.

After this short comparison, you can know that which type of machines to make manure pelletizer can satisfy your demands. For example, if you want a granulating machine which has large production ability but without too much energy cost, the poultry manure rotary drum granulating machine is the best choice.

You may worry about that large poultry manure block and high moisture manure are not suitable for the fertilizer process. However, our animal waste fertilizer granulator can solve these problems easily. Here we use rotary drum granulation machines to give you a brief introduction.

Our machine can process large poultry manure block efficiently.

In our whole manure rotary drum granulation machine production line, compost and fermentation is an important part. They help grind the large manure block into powdery and control moisture. Besides, our granulating machine can also achieve this point in a certain way.

You can see there is a hammer in the package of rotary drum fertilizer granulator. It helps shake off the sticking raw materials. In the internal details of the granulator drum, you can also see the blades. They are casting orderly to make the raised materials into pellets in the rotary tube.

Our machine can control manure granules’ moisture exactly.

The main principal of rotary drum granulator machinery production is wet granulation, it requires granules moisture to be 30%-40%. Then the rotary drum will make granules by turning. You put adhesive into the materials. Then the granules will coalesce by the function of the adhesive. The pellets formed have the advantage of high quality, beautiful shape, strong wear resistance, high hardness by this way.

So that appropriate moisture is necessary for our granulating machines’ work. But if the moisture is much higher, there is also necessary to compost the raw animal waste in advance.

A Complete Manure Fertilizer Pelletizing System for Your Reference

This whole animal manure production line contains the following steps. There are some other animal manure processing machines for your reference in your plant. You can have a general understanding of how to make pellets from poultry manure.

Crushing and mixing process

1.Crushing: This step will crush large blocks of raw animal waste, which prepares for granulation. With the exception of rotary screen machine, you can also choose high output hammer crusher, which is the preferred crushing machine for large scale production of organic fertilizer.

2.Mixing: In this step, mixer evenly blends animal waste, which creates uniform fertilizer effects and makes preparation for granulation.

Granulation and polishing process

In this step, powdery becomes pellets by SX equipment like new type organic fertilizer granulator, rotary drum churning pelletizer and rotary drum granulator. If you need to make the pellets more beautiful and uniform, you can adopt organic fertilizer polishing machine after granulation.

Drying and cooling process

In this step, you can cool the temperature of manure pellets and remove parts of moisture in pellets. Besides, you can adopt rotary drum drying machine, rotary drum cooling machine and natural gas burner or hot blast furnace. At the same time, the three machines are used together. Natural gas burner or hot blat furnace offer hot wind to rotary drum drying machine, which can dry manure pellets and evaporate some moisture. Rotary drum cooling follows the drying machine, which is used for further removal of moisture and lowering temperature.

Screening process

You can remove unqualified pellets by this step. In addition,you can apply vibrating screen machine, which adopts the cylindrical eccentric shaft oscillator and the partial block to adjust the amplitude. Moreover, it is featured with long materials screening line and multiple screening sizes.

Packing process

The final step of organic fertilizer production is packaging, which makes organic fertilizer more easily for storage and transportation. At the same time, we provide hot sale double (single) bucket automatic packing scale. All these auxiliary machines can save workforce and improve work efficiency.