How to get more profits from mineral? It is an ideal choice to process it into mineral fertilizer granules. Then how to make mineral into quality fertilizer pellets? In general, there are two granulation methods for your choice. Dry granulation method and wet granulation method. You can choose the most suitable one according to your needs. Then SX can provide you with professional mineral fertilizer granulator for dry and wet granulation methods. And besides this, we can also offer you other equipment to help you setup a production line for better mineral granule making. So on 26th April 2024, a customer from Brazil inquired about a mineral fertilizer granulator. And we discussed with him about granulator details.

What method is commonly used in making mineral into pellets?

This Brazilian customer didn’t know what granulation method is suitable for him, he hoped that we can recommend it. In general, there are two kinds of granulaion methods you can use in granular mineral fertilizer production. They are dry granulation method and wet granulation method. But what is the difference between them? Which one is more suitable for you?

Dry mineral granulation method

Dry granulation is popular with fertilizer manufactures who want to start a small scale mineral fertilizer granulation. Because it has characteristic of low investment, less area occupation, simple process, easy operation, etc. The dry mineral pellet machine mainly makes use of physical extrusion between rollers to turn powder into mineral fertilizer pellets. So, there is nearly no water involved. And because it also requires that feeding material has a low moisture content of below 10%. Under the help of dry granulation machine, you can finish mineral pellet manufacturing without drying and cooling. This is beneficial for reducing the cost and space of fertilizer mineral granule production.

Wet mineral granulation method

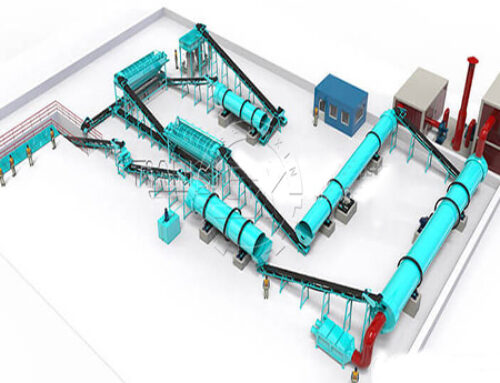

But for commercial mineral pellets manufacturing, we recommend you adopt wet granulation method. For one thing, it can meet your requirements of making mineral fertilizer pellets. This can ensure the sufficient supply of mineral fertilizer for your customers. For another, after wet granulation, your mineral fertilizer granule will have characteristics of beautiful appearance, uniform particle size, low pulverization rate, etc. Therefore, it has higher competitiveness in the market and you can make more benefits from mineral processing.

Which mineral fertilizer granulator is suitable for you?

In order to help Brazilian client produce quality mineral fertilizer granules easily and quickly, we especially design professional mineral fertilizer pellet making machines according to those two mineral granulation methods. Including disc granulation machine, double roller granulator and rotary drum pellet equipment. You can compare the performance of them in design, capacity, cost, etc, and then purchase the right one.

Leave A Comment