Which Granulation Machine is Suitable for Bio Fertilizer Making?

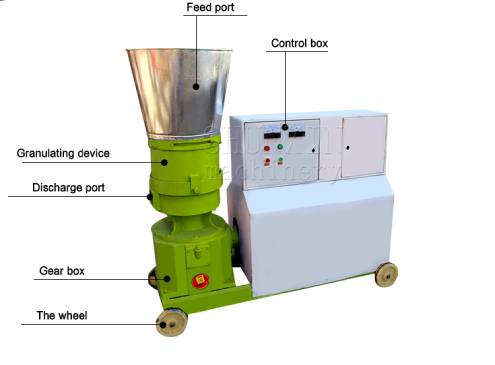

The client from Vietnam had a animal manure treatment plant, so he wanted to use animal manure to prepare bio fertilizer pellets. Then first of all, it is essential to buy a type of suitable chemical pellet making equipment.

In this way, compared with using disc and drum granulator, there is no need of drying and cooling in bio flat die fertilizer granulation plant. So you can reduce the cost of fertilizer dryer and cooler purchasing and meet you shape’s requirement.

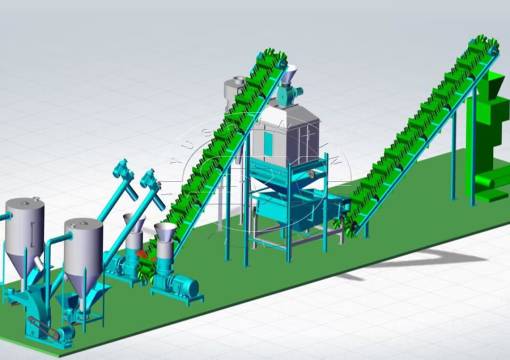

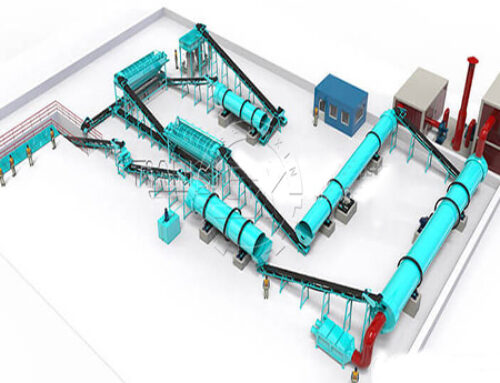

How Much can you Buy a Latest Flat Die Fertilizer Granulation Plant?

Now, there are various flat die granulators on the market. You must see the model and specifications of the flat die pellet machine, before you pay for it. Because the prices of flat die granulators of different specifiations are different, so it leads to the flat die fertilizer granulation plant’s price is different. Generally speaking, the higher the capacity of the production line, the higher the price.

If you want to buy a latest flat die fertilizer granulation plant now, you can contact us and our latest quotation will be provided to you for free.

Leave A Comment