Why Should you Make Limestone Pellets in Australia?

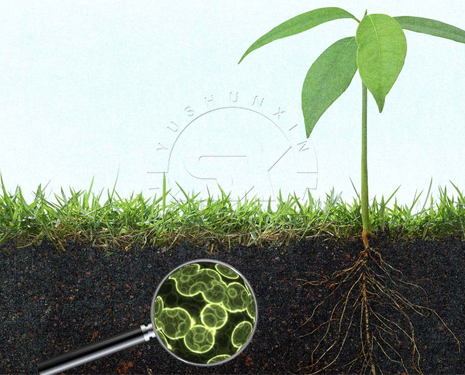

Customer from Australia wanted to produce limestone pellets, but we must first know what benefits it can bring us. First limestone particles are generally used to increase the pH of acidic soils and reduce the content of water-soluble aluminum in the soil solution. Water-soluble aluminum in soil is detrimental to root growth of many plants. A large part of the stunted growth of crops on acidic soils is due to the poisoning of water-soluble aluminum. In addition, Australia is rich in limestone, and the raw materials are abundant. So the production of limestone pellets can:

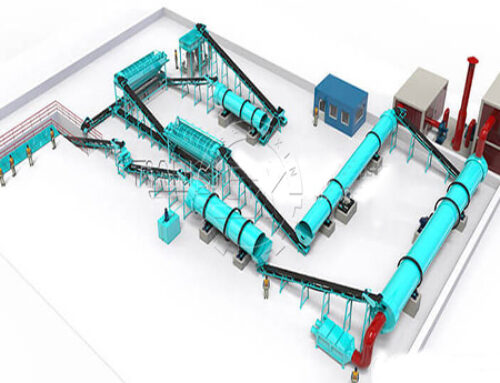

How to Make Limestone Pellets in Drum Granulator?

Then after knowing the benefits of producing limestone pellets, the most important thing is how to produce them. Customer from Australia wanted to have a limestone fertilizer pelletizing plant. So we recommend him to configure a rotary drum granulator production line.

Leave A Comment