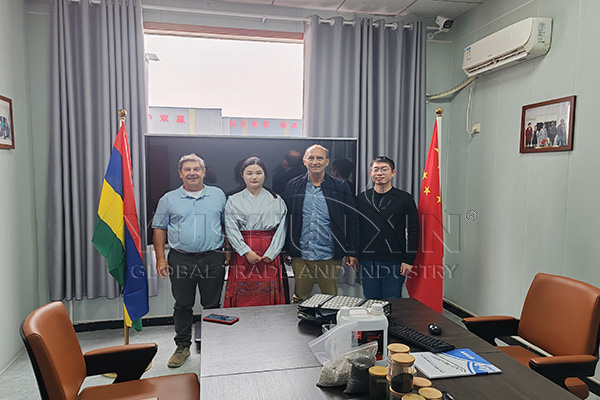

On January 26, 2024, a customer from Mauritius inquired about wanting to produce organic granular fertilizer with chicken manure, seaweed and sawdust as materials. This customer’s main business is the production of organic fertilizers from sea by-products. For this, after planning and discussing the detailed information, we customized a solution specifically for him. The following are the special information in this case:

What materials can make high quality organic fertilizer granules?

This Mauritian client prepared to turn chicken manure, sawdust and seaweed into high quality organic fertilizer granules. Why do you choose them for organic fertilizer pellets production? What nutritional value do they have?

To sum up, mixing chicken manure, wood chips and seaweed to produce organic fertilizer is a good choice. And our organic fertilizer making equipment can fully adapt to these raw materials. Both parties reached a consensus.

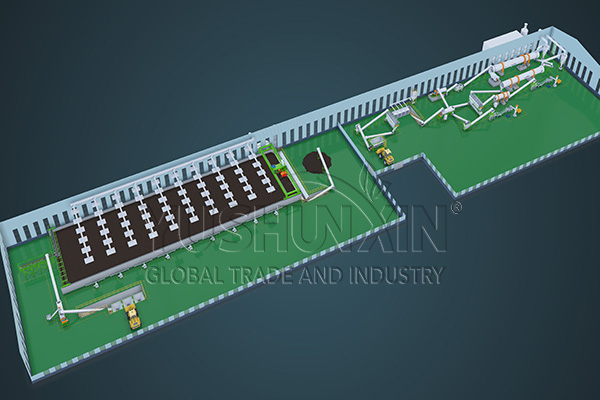

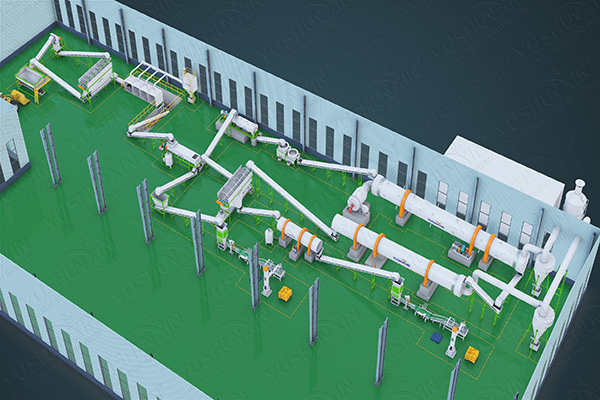

What is the layout of organic fertilizer production project in Mauritius?

After choosing the suitable raw materials, we provided customer from Mauritius with two types of organic fertilizer production projects. Powdery and granular. The fertilizer machine used in these two organic fertilizer making lines is different.

After introducing the above two solutions to the Mauritian customer, he finally chose the organic fertilizer granule line. And we discussed the details based on his fertilizer production plan.

Leave A Comment