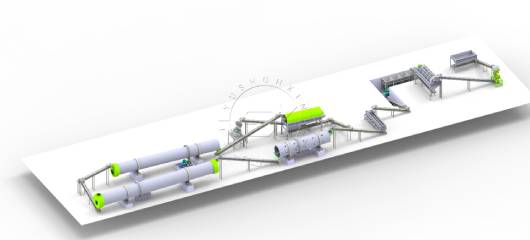

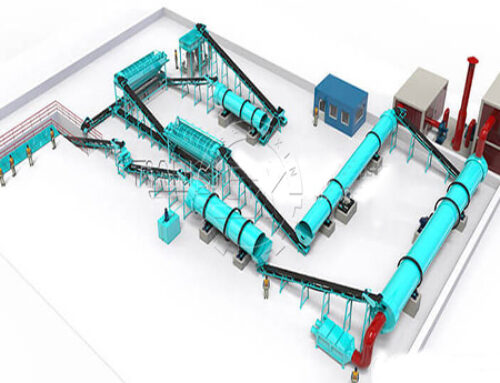

When you make pellets with wet granulation process in the fertilizer granulation plant, these finished fertilizer have more moisture. But if you package them directly, it will lead to make unqualified pellets. So you need to dry them through drying machine in your production line. Like the customer from American, who inquired about drying machine on 12th March 2023. Finally, after discussing the details, he chose our granulate dryer in his production line. The following are the specific details of communication in this case.

Top 2 Types of Drying Machine for Animal Manure Disposal in American

Usually different fertilizer suppliers have different requirements for granulate dryer. Because there is disparity in their drying conditions. Such as material, it can be chicken manure and cow dung; capacity, it is small, medium and or large scale drying. So we design various drying machine for customer’s choice.

Leave A Comment