Limestone Powder Granulator Machine

What Method is Used in Limestone Powder Granules Production?

If you want to convert limestone powdery fertilizer into granules smoothly, it is necessary to know how powder forms into pellets. In generally, it mainly relies on two forces to make limestone powdery into granules. One is cohesive force between materials caused by liquid binder. Another is the resulting mechanical force of machine working. So usually, there are two kinds of granulation methods you can adopt in granules production.

Wet Granulation Method for Commercial Limestone Powder Granules Making

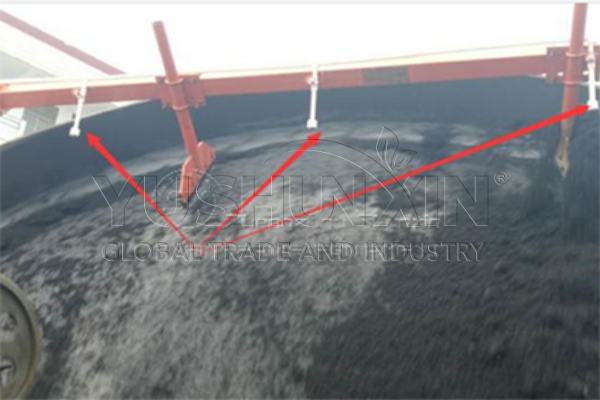

Do you plan to prepare limestone powder pellet for commercial purposes? We recommend you choose the wet granulation method, which makes use of not only liquid cohesive force but also resulting mechanical force of machine working to process limestone powder fertilizer into granules. So the final fertilizer particles have characteristics of beautiful appearance, uniform particle size, low pulverization rate,etc. In order to make it more convenient to add liquid, we especially design spray devices for our wet granulation machines. Moreover, in order to fully meet your requirements, we design wet granulation machines with different mechanical forces. Therefore, there are disc granulator and rotary drum pelletizer for your choice.

Dry Granulation Method for Low Cost Limestone Powder Granulation

Dry granulation equipment is more suitable for those who want to prepare limestone granular fertilizer in a simple process or at a low cost. It mainly relies on an extrusion force between two rollers to turn limestone powder into pellets. So there is nearly no water involved. In addition, the moisture of feeding material is below 10%. So you can save your money on drying and cooling, then finish the granulation of small scale limestone pellets making at a low cost.

What equipment is needed for limestone pellets dry granulation?

The typical limestone dry granulation machine is double roller pellet making machine. In the process of granulation, the rotating roller of extrusion pelletizer will press limestone powder into mold. This mold will form limestone powder into small particles with the required diameter. What a simple process!

How to Buy a Suitable Limestone Powder Granulator Machine according to your Expectant Capacity?

When selecting limestone powder granule production machine, you need to consider from many aspects, especially the capacity. For small medium and large scale powder granulation, you need to choose different types of limestone powder pellet making machines.

How Much Does Limestone Powder Granules Making Machine Cost?

The price of powder granules making machine is an item you must pay attention to. But there is no doubt that you can buy powdery pellet making equipment at a favourable price in SX. Because we are a source factory for fertilizer equipment manufacturing, there is no extra charge during the transaction. In general, the prices of the above powder granulators are as follows:

How to adjust the size of granules during limestone pellets production?

If you want to make limestone granules of different sizes, our equipment also can meet your requirements. You can change limestone pellets size by following ways:

How to Establish a Limestone Powder Granulation Plant?

If you want to improve the quality of your limestone granules and earn more profits, we also can provide you with limestone powder granulation making plans according to your requirements. For different capacities, we can provide you with small limestone powder granulation making line and large scale limestone powder granules production system. And we also have limestone powder pellets manufacturing project for different budget, factory area, etc. In general, these limestone powder granulation making lines will contain equipment of batching machine, crusher, mixer, granulator, screener, dryer, cooler, dust collector, coating machine, packaging scale and conveyor.

What can you do to improve the quality of limestone pellets?

After limestone granulation, you will find that there still are some items you want to improve. For example, uneven appearance, excess moisture, easy to stick after long time storage, etc. ls there any solution for them to improve the quality of limestone granules? The answer is yes. There are some fertilizer processing machines can help you a lot.

Why so many limestone granules suppliers to choose to buy limestone powder granulator machine from YUSHUNXIN?

When you want to buy limestone powder granulator machine, SX fertilizer production machine factory will be your ideal choice. Why?

Wide applications

Limestone powder granulator from SX has high adaptability, so it can be used for a variety of materials. Including limestone, zeolite, alfalfa, bentonite, chicken manure, sludge, biogas residue, etc. So you can use our equipment with confidence.

Advanced technology

During limestone pellets equipment manufacturing, we adopt many advanced equipment, Including plasma cutting machine, laser cutting machine, automatic bending machine, etc. Guarantee the manufacturing accuracy of the granulator.

High quality equipment

All SX fertilizer equipment is made of high quality steel, which can increase the ability to resist wear and corrosion. So you can use it for a long time. For this, we can provide you with relevant certificates.

Economical price

SX is a source factory of limestone powder granulator, there is no extra charge for you. So we can provide you with high quality equipment at a favourable price. In addition, we can design the limestone pellets granulating production line according to your actual conditions, which include your budget.