New Type Organic Fertilizer Granulator Production Line

New type organic fertilizer granulator production line, during which the granulation machine usually is the core. Thus, you choose this granulation production line mainly have two reasons. On the one hand, new type organic fertilizer pellet equipment’s advantages have attracted you and satisfied your demands. On the other hand, you have considered that you can have a more stable and continual fertilizer granulation by setting up a complete production line.

Read this passage, and you can know how new type organic fertilizer granulator machine’s and production line’s performances subsequently. Besides, you can also know how they operates in the real case. Thus, you can choose your favorite new type organic fertilizer granltion line.

Reasons of Adopting New Type Organic Fertilizer Granulating Machine in Your Plant

With this granulator in your fertilizer plant, therefore, you can make different kinds of fermented organic matter into granulates. The pellets’ diameters are usually 3-10 mm. Besides, you can adjust the diameters of the pellets by controlling the amount of the material mixing and the rotating speed of the main axle.

In the making of a new type granulator organic fertilizer, our machine adopts wet granulation. When a new type organic fertilizer granulator machinery works, you put adhesive into the raw materials. Then the granules will coalesce by the function of the adhesive. Then under the function of stirring tooth, the pellets’ hardness will improve greatly. The pellets’ strength is up to 20-25N. Certainly, the finished products by the new technology organic fertilizer plant granulation have the advantage of high quality, beautiful shape, strong wear resistance, and high hardness.

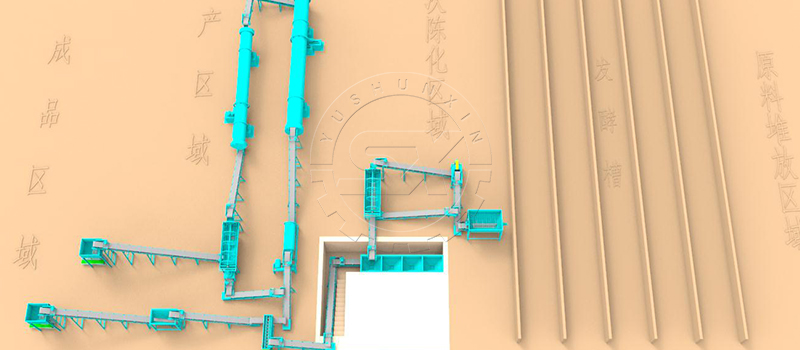

You Can Design Your Granulation Factory’s Layout Flexibly

How to design your new type organic fertilizer granulator production line in your factory flexibly? Here are mainly two ways. On the one hand, you can omit mixing system because new type granulation machine can mix raw materials in a certain way. On the other hand, according to the wet granulation method of new type organic fertilizer granulating machine, drying and cooling are necessary procedures in your plant.

You may notice that some procedures are cut in the new type organic fertilizer pellet making factory. For example, mixing system. In fact, according to the working principle of new type granulating equipment, there is no need to dry and mix the raw materials. One reason is because the stirring tooth can mix the pellets and make the pellets crash with the blades and the tube wall to granulate pellets. The other reason is that the machine adopts wet granulation. Certain moisture degree is possible, of course.

Instead, drying and cooling is a necessary and important part in the production line. As our new type fertilizer granulator adopts wet granulation, pellets made by wet granulation must go through dryer. Thus, lowing down the moisture to the package standards: 20%-25% moisture. If not, the pellets will use a longer time to low down the moisture under the natural condition. They will become much easier to stick with each other with high moisture obviously, which will bring a lot of harms to your pellet products and businesses.

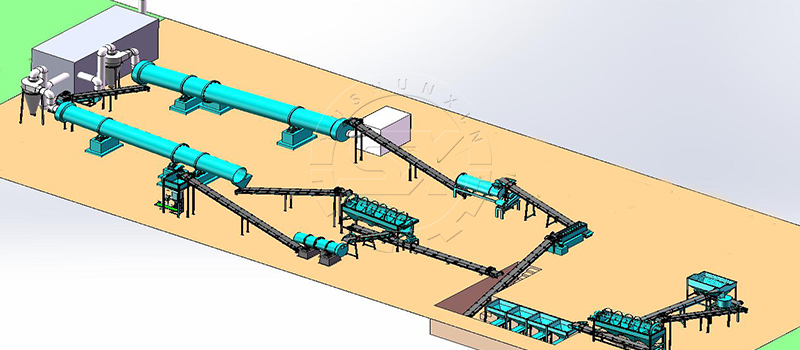

In the fertilizer granulator production line, we usually go through these procedures: fermentation and compost, grinding system, granulation system, drying and cooling system, screening system, packaging system. They all works for the stirring teeth granulator’s stable running.

Fermentation and compost:

We ferment and compost raw materials for decomposition and recycling the nutrient. You can choose poultry manure, agriculture waste, and some chemical materials to granulate organic fertilizer or compound fertilizer.

Grinding system:

It can crush the big solid blocks into small pieces, fine powder or powder to help make much more smooth and high quality fertilizer pellets. Through the belt conveyor, crusher transmit the appropriate size raw materials to the granulation part, and unqualified granulated pellets can be regarded as returned materials to send back to the crusher.

Granulation system:

The new type organic fertilizer granulator equipment uses mechanical agitation force and aerodynamic force to achieve granulation. They can make fine powder materials granulate continuously.

Drying and cooling:

After granulation, drying and cooling are necessary for the granules. They control pellets’ moisture and temperature for packaging. Our factory provides the detailed parts for the whole dryer and cooler working line.

Screening system:

Through the different sieve sizes’ separation, qualified pellets in size and shape will go to the next part, while qualified pellets can be recycled to granulate again. In this way, granulation sieve has an important role in producing high quality pellets.

Packaging system:

In the whole production line, package the qualified pellets into sack is the final part. Packaged organic or compound fertilizer makes you transport and sell fertilizer in a large scale more easily.

The Benefits by Building A Newly Granulator Production Line for Making Organic Fertilizer

On our website, one set of new type organic fertilizer granulator’s price is $8000-25000 now. You can choose the model according to the production capacity. When we calculate the cost of whole new type organic fertilizer production line, which includes six important fertilizer production parts, fermentation and compost, grinding system, granulation system, drying and cooling system, screening system, packaging system, the total cost can up to $110000-550000. We still need to calculate them according to your factory area, labor cost, energy consuming and electric consuming etc. to give you a more exact cost. The price mentioned here is for reference.

Besides, we can also help you to make a small calculation about your revenues. You can give us your market price in your inquiry, or we calculate them according to China’s fertilizer market. Generally, one tons of granular pellets can sell $150-200, and one tons of granular powdery pellets can sell $100-150. Our new type organic fertilizer production line can make 500000 tons pellet easily. You can soon make benefits from this production line.