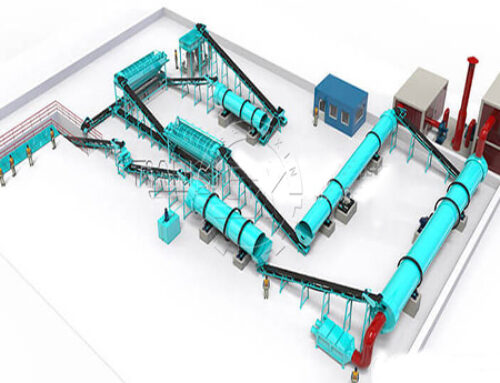

How to Produce Fertilizer with Wet Granulation?

The biggest difference between wet granulation and dry granulation is the need for drying and cooling after granulation. The production process will be more complicated. So how to use wet granulation technology to make fertilizer pellets?

Drying&Cooling

In order to facilitate your subsequent transportation and sales, the bagging of granules requires moisture below 25%. So you need to dry and cool. A lot of exhaust gas will be generated during the drying process, we can provide you with a dust collector to ensure the wet granulation production environment.

Packaging the finished fertilizer

Finally, you can package the finished fertilizer. We have high-speed packaging equipment with high packaging precision, and the weight of each bag is consistent. If you have more budget, you can also equip a palletizer. It can help you better handle your packaged fertilizer.

What is the Price of Wet Granulation Equipment?

you need to know the price of equipment depend on the model and function. Higher capacity, the increase of function and complicated production process will raise the cost of equipment. So as a manufacturer of wet granulation equipment, SX has its own production factory. That is to say, we can provide you factory price and do not have middleman’s price difference for customers. And SX can also provide you a suitable fertilizer production project according to your budget and requirements.

Wet Granulation Equipment for You to Choose in SX

As mentioned above, you can use rotary drum granulator and disc granulation machine with wet granulation. Both of them have high granulation rate and you can apply them to various fermented organic waste,such as chicken manure, cow dung and so on. Then our professional engineer will introduce them for details.

dic pelletizer for wet granulation

This machine is suitable for making both organic fertilizer pellets and compound fertilizer pellets. The capacity of this machine is 1-6 t/h. It is suitable for small scale wet granulation production. In addition, it has a small footprint and is easy to transport. And the establishment rate can reach more than 93%. The whole is made of stainless steel, which is not easy to corrode. You can adjust the size of the particles according to the degree of inclination of the disc. And add a spray device on the disc to adjust the moisture of the particles at all times.

rotary drum granulation machine for wet granulation

You can adapt drum granulator to produce spherical organic fertilizer. The capacity of this machine is 1-30 t/h with large scale wet granulation production. There are knives in the drum to increase the friction between the material and the wall of the drum to promote granulation. In addition, a hole and a small hammer to prevent sticking to the wall are provided outside the cylinder wall. During the rotation of the drum, the small hammer will strike accordingly to prevent the material from sticking to the drum wall and avoiding waste.

The above is the details of wet granulation. And we also have dry granulation production to provide for you. Inquiry us for details.

Leave A Comment