Applicable equipment for dry granulation includes double-roll granulation machine and flat die granulator. These two produce compound fertilizer and organic fertilizer respectively. There are too many types of raw materials for compound fertilizers, and the ingredients inside are complex. Dry granulation can well guarantee the retention of raw material nutrients. Since the raw material is not uniform in size, you can produce it after crushing. Next, our experts will explain the details of dry granulation for you.

Why Should you Choose Dry Granulation to Make Fertilizer?

Dry granulation is usually suitable for the granulation production of compound fertilizers and blended fertilizers, such as NPK fertilizers and BB fertilizers. If you use wet granulation to produce these two fertilizers , the ingredients in them may react chemically when they meet water. And it will also lead to the volatilization of nutrients, which will reduce the nutrient content of the produced fertilizer. However, dry granulation is suitable for raw materials with a moisture content of 10%-15%, and you do not need to add additional water. Therefore, this process can well lock the nutrients in the raw materials, and the granules produced have higher nutritional value.

How Do You Dispose of the material Before Producing Fertilizer with Dry Granulation?

What Equipment Can You Choose to Use Dry Granulation Technology for Fertilizer Production?

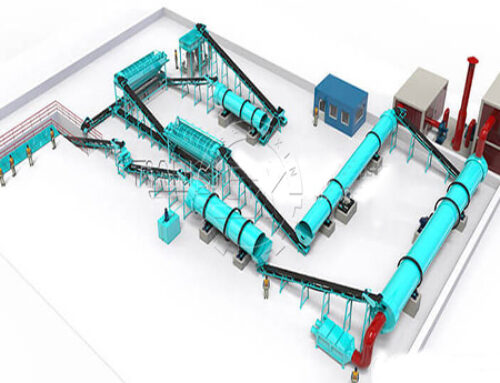

The dry granulation process can not only produce compound fertilizers and blending fertilizers, but also organic fertilizers. The equipment you use to produce different fertilizers is also different. To produce organic fertilizer you can use a flat die granulator. For compound fertilizers and blended fertilizers you can use double roller granulation machine.

Double-roller Press Pelleting Machine to Make Compound Fertilizer for Dry Granulation

The production of fertilizer by the double-roll extrusion granulator is to put the raw material from the feed hopper, and press it through the high-pressure roller body to form it. You don’t need to dry and cool after granulation, it can be packed directly. Compared with wet granulation, the production process is simple and the production cost is reduced.

Leave A Comment