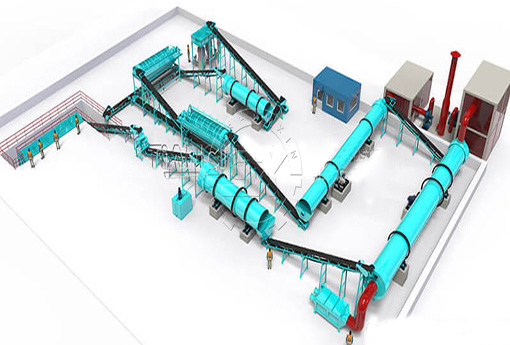

NO.1 Limestone Granulation Plant

Before buying limestone granulation plant, you need to consider 5 aspects: capacity, processing method and cost. For this, SX can provide you more suitable plant for you.

What Need to Consider When you Buy Limestone Granulation Plant?

If you are interested in limestone granulation plant, you need to pay attention to how to purchase suitable limestone manufacturing equipment. Then for limestone granules making equipment selection, you can consider it from the following items:

Capacity

Capacity is an item you must pay attention to when selecting limestone pellets equipment. For example, when stating a small scale limestone granules processing, we recommend you choose SXYZ-2800 disc granulation machine, etc. And for large scale limestone particles making, it is advisable to buy rotary drum pelletizer, etc.

Processing Method

Moreover, processing method is also an important factor that affects your limestone particles processing equipment selection. Provide you use wet granulation method, it is necessary to buy dryer and cooler for excessive moisture removal. However, when you use dry granulation machine for limestone pellets making, it is dispensable to purchase dryer and cooler.

How Much it Costs to Setup Limestone Pellets Making Line?

To set up a small scale limestone granulation plant, you only need to purchase some indispensable limestone making equipment in the whole limestone granules production line. So, it saves a lot for you to investing a new mineral pellets production business. If you want to set up a large scale limestone pellets plant, we also have large limestone equipment for you to choose. Besides, SX can provide you high quality limestone pellets making equipment at factory price. So, if you have any questions about SX small scale limestone granules production, just contact us freely.

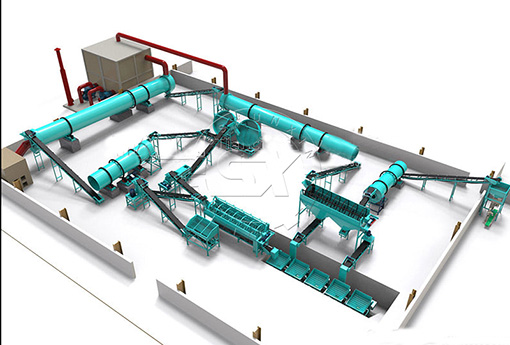

NO.2 Zeolite Granules Production Line

If you want to make zeolite pellets, granulator is necessary. But what granulation machine is suitable for you to produce zeolite granules? SX can recommend you 2 granulators, which is hot selling from customer.

Pan Granulator for Small Scale Zeolite Pellets Production

For making zeolite pellet in a small scale, most mineral pellets manufacturers choose our pan granulation machine. Why? There are three reasons.

Rotary Drum Granulation Machine for Large Scale Zeolite Granules Making

But for large scale zeolite pellet making, the most popular equipment is rotary drum pelletizer. Why? What are the benefits of rotary drum granulation?

Finishing Large Scale Zeolite Granulation Quickly

Compared with pan pelletizer, rotary drum granulation machine can complete large scale zeolite granulation more quickly. Because it has a large capacity, which is high to 30 t/h. Hence, within the same time, drum granulation equipment can make 2-5 times as many granules as other zeolite granulators.

Reducing Erosion to the Pellets Machine

For large scale zeolite pellets processing, erosion-resistance is an item most mineral granules supplier focus on. But using drum pellet production machine is a perfect solution. For one thing, the body is made of high strength alloy steel, which is wear-resistant and anti-erosion. For another, we especially equip it with rubber lining, angle irons and cleaning holes to prevent sticking. This can further improve the machine’s erosion-resistance. So drum pelletizer can work to prepare zeolite granules for you for a long time.

Leave A Comment