Extrusion Granulator Fertilizer Plant Cost

With the increasing demand for compound fertilizers and the need for NPK fertilizer production. More and more companies choose to extend their business to the field of compound fertilizer production. And most of them plan to build a extrusion granulator fertilizer preparation plant. During this process, compound fertilizer manufacturing plant cost is an important factor in which method and equipment they choose to produce compound fertilizer. As a professional fertilizer equipment manufacturer, SX designs compound fertilizer production lines with different budgets for your choice. If you have any special requirements, we also can provide customization service for you. So if you are interested in it or want to know more details, please contact us quickly.

What is the Cost of Extrusion Granulator Fertilizer Plant Set up?

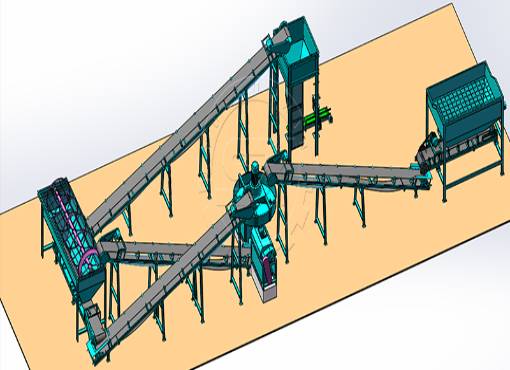

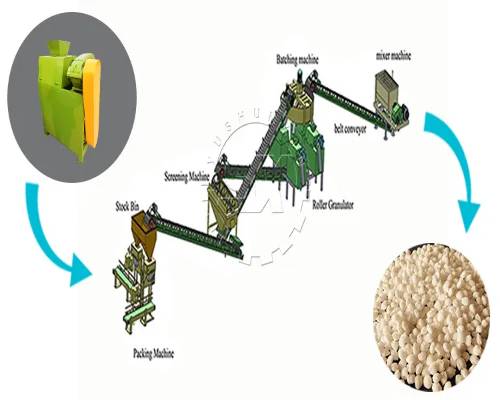

Generally speaking, you can use double roller press granulator to make compound fertilizer. And for this, SX can offer you professional granular compound fertilizer production system. How much do it cost?

How Much Does it Cost to Start a Small, Medium and Large Scale Compound Fertilizer Plant?

Capacity also plays an important role in the investment of compound fertilizer plant setup. Usually, the larger the output of compound fertilizer production, the higher the price.

1-5 t/h Small Scale Compound Fertilizer Plant Cost

Provided you want to start an small compound fertilizer production plant, you must buy compound fertilizer machines with a small capacity. Such as static batching machine, semi-wet material crusher, SXPJ-1800 disc crusher, double roller granulator, SXGS-1240 screener, single bucket automatic packing scale and so on.

They generally have a lower price than the large output one. Therefore, the cost of 1-5 t/h compound fertilizer pellets making line is $ 102,311- $ 134,709.

5-10 t/h Medium Scale Compound Fertilizer Factory Investment

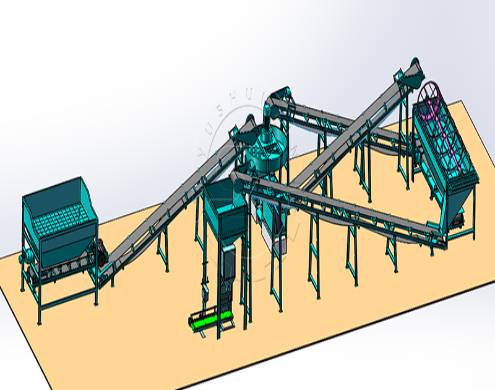

When the scale of your compound fertilizer increases, you need to replace your small fertilizer processing machines. For 5-10 t/h medium scale compound fertilizer factory setup, it is advisable to use dynamic batching machine, SXFLF-800 new type vertical crusher, double shafts horizontal mixer, extrusion granulator, SXGS-1560 screener, double bucket automatic bagging machine and so on.

In this way, you need to invest $ 134,709-$ 213,310 in 5-10t/h granular compound fertilizer plant setup.

10-15t/h Large Scale Compound Fertilizer Plant Budget

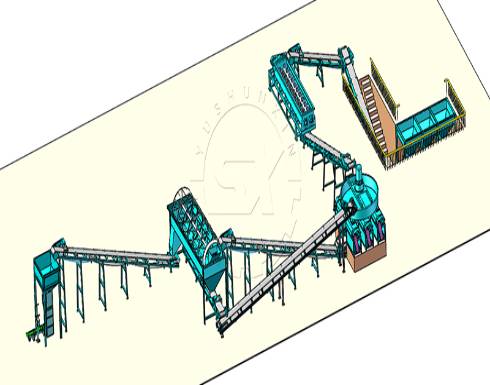

Then how much does it take to set up a large scale compound fertilizer plant with a capacity of 10-15 t/h? It will cost $ 213,310-$ 300,000 to produce compound fertilizer pellets.

For this, you can buy dynamic batching machine, SXFLF-1000 new type vertical crusher, SXWJ-1630 horizontal mixer, double roller granulator, SXGS-2080 screener, double bucket automatic bagging machine and so on.

How to Design the Extrusion Granulator Fertilizer Plant at the Best Cost?

In order to save planning investment, shorten construction period, reduce production cost and make full use of land resources, you can divide the factory into the following three parts according to production needs and use function.

Production Area

The production area is the main part of the factory area. Therefore, it is very important to design the production area reasonably. we have engaged in the fertilizer equipment production for many years. We can give you some suggestions about designing the compound fertilizer production area.

Work and Living Area

When designing this area, you should consider compound fertilizer production place. For working staff’s health and normal living, you should arrange living area at upwind position of production area.

Public Facilities Area

In order to make it more convenient for staff to work and transport raw materials and products, the public facilities area should be set up near the living area.

How to Build Extrusion Granulator Fertilizer Plant with Lower Investment?

There are many factors that affect the cost of building a compound fertilizer plant. High quality equipment, reasonable layout, reliable equipment manufacturer and buying place.

High quality fertilizer processing machines usually can be used for a long time. So you can spend less on changing broken fertilizer equipment. For this, SX fertilizer equipment is your ideal choice. Because it is mainly made of high strength materials and all areas in contact with fertilizers are made of corrosion resistant steel. And we can provide guidance on how to operate it correctly and how to maintain it. These can prolong the service life of your compound fertilizer machine.

Reasonable layout also can reduce your compound fertilizer manufacturing plant cost. We can provide you with a free project design according to the actual situation of your extrusion granulator fertilizer plant. You only need to tell us your materials, capacity, fertilizer plant area and budget. We can offer you free process design drawing, reasonable configuration plan, forward guidance according to your requirements.

Choosing a reliable fertilizer equipment manufacturer is important to build compound fertilizer manufacturing plant with low cost. For this, SX is an excellent choice for you. As a professional fertilizer equipment factory, SX has advanced technology and nearly 20 years experience in this field. So we can provide you with high quality fertilizer equipment and economical price. In addition, we can offer you guidance on installation and maintenance of double roller granulator to prolong its service life. If you want to buy high quality double roller pelletizer at a favourable price, please contact us immediately.

Where to buy is also a factor which influences your cost. The prices of buying double roller press granualtor online or offline, from distributor or source factory are different. It is no doubt that buying double roller granulator production line from source factory is more economical. So buying this plant from SX is an optimal option for you. Because it is a source factory for fertilizer processing equipment and there is no extra charge.