Disc Pelletizer for Sale

Disc pelletizer for sale is one hot sale type in organic fertilizer and compound fertilizer granulation machines. The machine is an overall arc structure. In this way, you add raw materials into the pan, and then start granulation under the function of the pan’s rotating. The process ends with the suitable size of pellets getting out of the pan. The granulation rate is up to 93% significantly. Besides, we can make all scales and all sizes pellets according to your needs. Browse the articles below for getting more details about the disk fertilizer granulator equipment.

What materials can you use for fertilizer granules making with pan granulation?

This disk granulator has strong adaptability in processing material. It is available for various raw materials for granulating. So there are many powdery matemials you can use to granulate. Whether the organic materials or compound fertilizer powders, this plate granulator can process them into granules effectively. Then what are common materials for pan granulation processing?

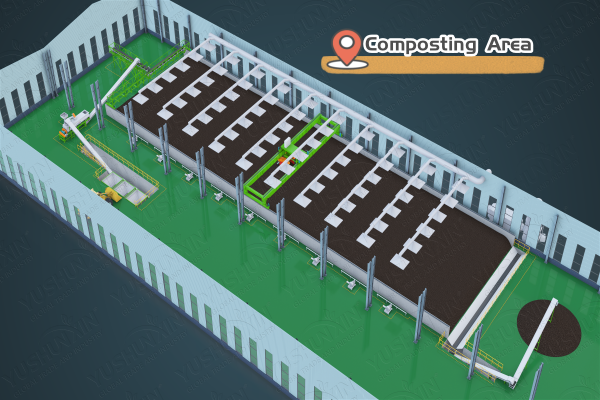

Organic Manure

It is widely used in organic fertilizer granules making plant. Our pan granulation machine can granulate the organic manure well. Organic manure is rich in nutrients. Generally, the composted animal manure compost fertilizer powder is about25%-30%. YUSHUNXIN manure pan pelleting equipment can process the powdery manure compost into granular. For example:

Compound fertilizer powder & Other powdery materials

Pan granulation machine is also applicable for pelletizing compound fertilizer powder. Whether you want to make NPK fertilizer granules or some other inorganic granular fertilizers, SX pan fertilizer granulator is suitable. Besides, you can also use it for processing some other powders, such as, ore, pulverized coal, cement, clinker, limestone, gypsum, clay and so on.

What angle does disc pelletizer work to make qualified fertilizer pellets?

In order to get suitable pellets, the angle design of pan granulation machine is adjustable from 1° to 90° in the line with flat ground in our company. The angle between pan plate and the flat ground decides the size of fertilizer pellets. When the angle reaches up to 65°, the size of fertilizer is smaller. The angle varies under 40°, the size become larger. Therefore, the proper angle (40°- 60°) is key to get qualified fertilizer granulars. During this period, qualified fertilizer pellets is available. Please following our instruction of guideline or our sales manage advice to operate disc granulation machine.

How to select an ideal disc granulator for your industry?

There are many specifications of the manure fertilizer disc graulators in SX. Do you know which one is suitable for your industry? How to choose the most suitable one for your fertilizer production plant? Now there are some tips for you.

Besides, if you have any requirements, SX, as a professional fertilizer machine manufacturer can provide you the best suggestions. In YUSHUNXIN, you will find the most suitable pan pelletizer for your fertilizer production.

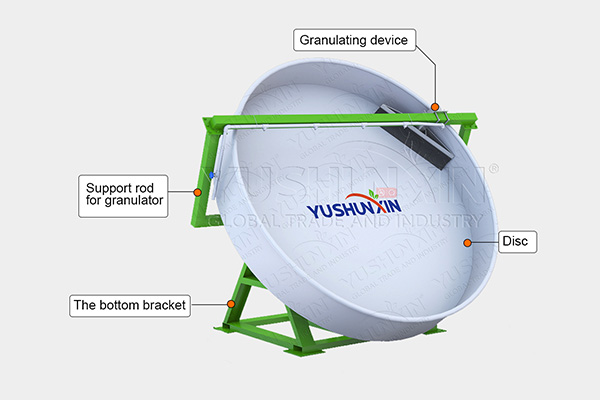

Our Pan Fertilizer Pellet Machinery’s Designs and Functions

The granulation tray is equipped with three outlets, which is convenient for intermittent production operations. Besides, the reducer and motor are driven by flexible belts to reduce the impact force and improve the service life of the equipment. The bottom of the granulation tray is reinforced with multiple radiant steel plates, which is durable. Thus, heavy, thickened, and solid base makes machines operate stably. The main gear of the granulator adopts high-frequency quenching, and the service life doubles in this way. The granulated face plate is lined with high-strength glass fiber reinforced plastics, which are anti-corrosion and durable.

These designs improve the pan fertilizer pellet equipment functions mainly from these aspects:

Our disc pelletiizer for sale uses wet granulation. The raw materials’ moisture requirements are 45%. If the moisture is too low, it’s harder to form ball-shape. However, if the moisture is too high, there will be bigger ball-shape granules. So the moisture control is very important. We provide hose and sprinklers to make them increase moisture at a certain amount and a fixed time. It makes sure the appropriate moisture with a low cost but high efficiency. Later, you can use dryer to control and low the moisture for package.

The disc granulator’s non-powered combination scraper clears the pan’s edge and bottom, and the corner-cleaning scraper clears the corner instead. With the unique cleanup technology of the disc body, the effect of cleaning and ball-shape granulation is excellent, and there will be no big mud lumps. Indeed, 90% of the diameter of the material ball is 3-5mm.

The pan’s angle is usually fixed for machine’s stable running. But it’s not absolutely. The slope angle of the large plate can adjust according to your needs. Angle spacers are used for flexible and convenient adjustment.

There are two ways for you to adjust the granules’ size: You can control the water spray system to control the raw material moisture. If you add less water into the materials, the smaller size granules you will get; if you add more water, the bigger size granules you can get. The other way is by controlling the slope angle. You can regulate the granulator slop angle to regulate the final granules size. Sharp slope will make smaller size fertilizer; slow slope will make bigger granules. You can adjust the pellets’ sizes from the aspect you want. But they both can adjust pellets’ size efficiently. Usually, you granulate the minimum 1-4mm size granules of good quality that can be 90% and without recycling.

From your specific operation aspects, firstly, you need to adjust the blade mixing structure. The distance between blade and bottom should be 5-10 mm. Don’t forget to screw the bolt tightly. Secondly, you can add the raw materials. As long as the materials don’t spill over the pan, it is enough. Thirdly, you can turn on the sprinkler valve and increase the moisture for granulation. Lastly, you can wait for the formed pellets get out of the pan automatically.

From the machine’s working method, the raw materials powder is mixed evenly by pre-adding water, and then put into the pan. With the rotation of the pan, the materials gradually roll in the pan and form spherical shape pellets. After reaching a predetermined diameter, it is discharged out of the pan and then transported to the next process. And that is the whole procedure for disk fertilizer granulator machine works.

Why so Many Fertilizer Manufacturing choose Disc pelletizer to Make Granules Fertilizer?

From past data, we found that many fertilizer suppliers buy disc granulator for their fertilizer pellets production plants. Why? From the feedback of our customers, we summarized three reasons as follows:

Various Types of Pan Granulators for your Choice

To fully meet the requirements of ferilizer suppliers, we especially design disc pelletizers with different capacities. Therefore, when you need small laboratory ferilizer pan granule machine, we can offer you SXYZ-1500, which has a minimum output of 0.5 t/h. And for those who want to dispose of animal manure in the farm, we can offer you disc granulator with a capacity up to 6 t/h, that is, SXYZ-3600.

High Granulating Rate

Our disc granulation machine has a high granulating rate of over 93%. This means this pellet machine can produce more required fertilizer pellets with the same amounts of raw materials. So you can complete process fertilizer powder into granules quickly and reduce the material waste.

Favourable Price

The favourable price is also an important advantage which attracts fertilizer production businesses to purchase pan pelletizer. Generally speaking, the price of a disc granulator is $ 1,000- $ 16,000. Why does it has such an economical price? For one thing, it has a compact design and a capacity of 0.5-6 t/h. The smaller the capacity, the lower the price. For another, SX is a source factory for fertilizer equipment manufacturing. So there is no extra charge during the transaction.

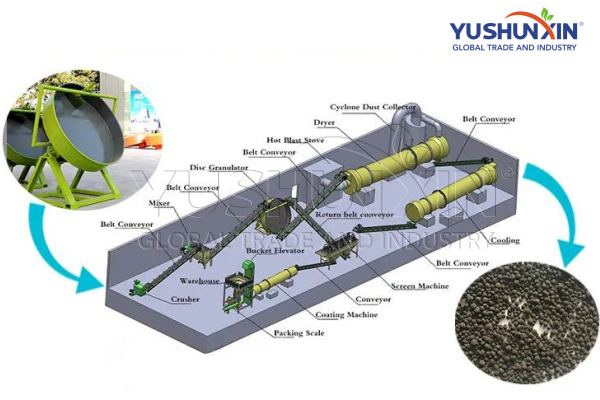

How to use a disc granulation system to make qualified fertilizer pellets?

When you prepare to make high quality fertilizer pellets, you need to establish a disc granulation system. According to fertilizer type, there are two types of disc granulation plants for your choice.

Organic fertilizer disc granulation line

Organic fertilizer disc granulation line

Dewatering machine → compost turner → crusher → mixer → disc pelletizer → screening equipment → dryer → cooler → coating machine → packaging equipment

Two Months To Have A Disk Fertilizer Pelletizer Production Line for A Customer in Indonesia

One of our customers is in Indonesia. The customer knew our company on the website and communicated a lot with our employee on October 23th. The customer stressed that the key is raw materials. Then the customer was going to visit our factory in November.

After visiting, the customer set the plant line approximately. As our employee communicated with the customer about the materials and details well, and solved the customer’s most problems and worries, we gave the customer quotation soon on November 28th.

Later, the customer negotiated with our employee more about the quotation.

On December 13th, customer gave the payment for the disk fertilizer granulator making machine production line. It only costs two months for Indonesian customers to have a disc fertilizer granulator machinery plant.

The most important reason is that we have rich experience in selling fertilizer production lines on the base of factories. Whatever problems and puzzles are welcome and our employees are going to solve them soon at our highest level. High efficiency and high quality service are obvious advantages of our disc pelletizer foe sale.