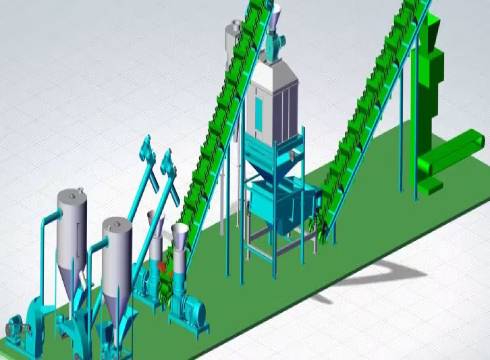

Flat die granulation line is widely used in organic fertilizer production. It can turn powder chemical material into granules at a lower cost. Because it adopts dry granulation method, which makes organic fertilizer particles only by physical extrusion force. And there is nearly no water involved in organic fertilizer making process. So you don’t need to spend on fertilizer pellets drying and cooling. In addition, it also has characteristics of less energy consumption, high granulation rate, easy operation, etc. This is the reason why more and more fertilizer choose flat die granulation line for their fertilizer plant.

For this, we have some successful cases. For example, a customer from Congo wanted to turn chicken manure into cylindrical particles. Hence, we recommended him the chicken manure flat die granulation manufacturing line. Moreover, SX also can provide him with this granulation line with different capacities and design layout according to his actual conditions. If you are interested in it, you can contact us at any time.

How Chicken Waste Flat Die Granulator Production Line to Process Organic Fertilizer?

Then Congolese client wanted to know what equipment is needed in this chicken poop flat die granulation line. In general, a complete flat die granulation manufacturing line consists of five stages, six types of fertilizer processing machines as follows:

Screw Dewatering Machine

For chicken manure fertilizer production, SXTS-180 screw dehydrator is your best choice. It adopts a stainless steel sieve with 0.3-0.5 mm holes, which can help you separate solids from excrement of chicken poop quickly. After dewatering, the water content of manure can be reduced to 30%-40%,which is more suitable for organic fertilizer making.

Chicken Waste Composting Equipment

Composting plays an important role in removing harmful substances from chicken manure. For chicken poop fertilizer fermentation, there are 3 types of fertilizer composting machines for your choice. For starting chicken waste composting in fermentation trench, we recommend you choose groove type composter. When you plan to start composting on the ground directly, you can buy windrow compost turner. In addition, if you want to finish composting of chicken waste faster, the in-vessel fermentation tank is your optimal option.

Semi-wet Material Crusher

After fermentation, you need to crush agglomerated compost into fine powder. It is beneficial for producing organic fertilizer pellets with a more smooth appearance. Then for 1-5 t/h chicken manure fertilizer pulverizing, semi-wet material crusher is an ideal choice for you.

Chicken Manure Mixing

Mixing can help you mingle various chemical materials evenly to prevent nutrients imbalance. And for powdery blending, we can provide you with a variety of fertilizer mixers. You can choose a suitable one according to your needs.

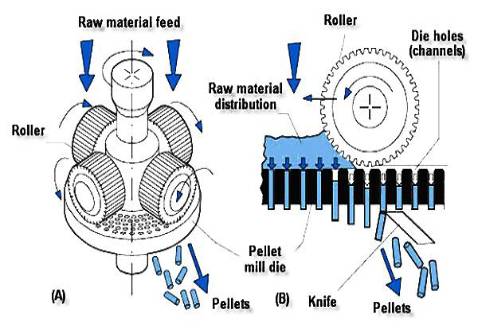

Flat Die Granulation

This is the most important step in fertilizer flat die granulation line. In this process, the mixed material will be granulated by extrusion force between three rollers and roller skin. After pressing granulating, organic fertilizer is more convenient for transport and storage. Because granular fertilizer can prevent nutrients layering during transport and storage. Here, we design flat die granulators with different capacities for your choice.

Fertilizer Pellets Screening

After flat die granulating, you may find that there are some fertilizer particles that don’t meet your requirements. Then how to separate them from qualified chicken manure fertilizer pellets? Rotary screening machine can help you a lot.

Chicken Manure Granules Packaging

Fertilizer packaging is the final stage of flat die pelleting line. In this stage, automatic packaging scale will bag granular organic fertilizer in 20kg/bag or 50 kg/bag in a short time. This is beneficial for transport and storage. And various packing capacities can meet different requirements for fertilizer suppliers.

Different Scales of Chicken Poop Flat Die Granulation Fertilizer Making Lines in SX

The capacity of flat die granulation line must be an item most fertilizer manufacturers pay attention to. Then Congolese client asked us “what is the capacity of this chicken poop fertilizer making line?” The answer is that it can produce fertilizer not only in a small scale but also in a large scale. Different capacity requirements have different project designs. Generally speaking, it can be divided into two cases.

Who Needs This Chicken Manure Flat Die Granulation Fertilizer Line?

This flat die granulator production line is absolutely an excellent chicken manure fertilizer making line. But the client from Congo asked us “is it suitable for me to prepare my own fertilizer? And where can this chicken manure fertilizer production line be used for?”

Leave A Comment