Fertilizer Granulator Machine Price

If you plan to buy a fertilizer granulator machine, price is an item you must focus on. But, it is usually not fixed, The fertilizer granulator machine price is closely related to the fertilizer types, method employment and equipment choosing, etc. As a professional fertilizer equipment manufacturer, YUSHUNXIN designs fertilizer granulator machines with different budgets for your choice. In addition, if you have any special requirements, we also can provide customized plan for your fertilizer granulator according to your requirements.

How much does wet granulation machine cost?

There are three wet granulators for your choice. Including rotary drum granulation machine, disc pelletizer and stirring teeth granulator. So what is the price of these granulators?

Rotary drum granulator for large scale granules making

Rotary drum granulation machine is suitable for large scale organic and compound fertilizer production. And the drum pellet making machine is equipped with large cylinder and robust base support. What’s more, there is an anti-corrosive inner lining inside the drum pelletizer. Thus, the rotary drum granulation equipment has a long-time service life. In general,the fertilizer drum granulation machine price ranges from $7,000 to $20,000.

Disc pelletizer for small scale pellets production

Under the help of wet granulation method, disc pelletizer can improve the compost granulation rate to 93%. Moreover, only needs 5-8 minutes, it can turn compost powder into pellets. So, the maximum capacity of this compost pellet machine can reach 6 t/h. Furthermore, it can make 1-8mm granules to meet different customer’s requirements. For this, when you choose this machine to make pellets, you only need $1,000-$20,000.

Stirring teeth granulator with higher hardness pellets

Although new type granulation equipment also belongs to wet granulation machine. It replaces the natural granulation method with stirring teeth granulation method, which makes use of high speed rotary mechanical agitation force and the resulting aerodynamic force to convert compost powder to organic fertilizer granules. Hence, from feeding to discharging, it only takes about 3-5 minutes. Moreover, the conglomeration rate is up to 97% . So, if you want to make granules with higher hardness, it is the best choice for you with $8,000-$25,000.

What is the price of dry granulation equipment?

For dry granulation machines, they are more commercial than wet granulation equipment. So, when you apply dry granulation method, you can select flat die pellet machine and double roller granulator.

Flat die pellet machine with low investment

If you plan to produce 1 ton of fertilizer granules per hour, we can offer you with SXPM-400 flat die granulator. In addition, provided you need a 2 t/h granulation machine, we also has SXPM-500 and SXPM-600 for your choice. Then their outputs are 1.5-2 t/h and 2-2.5 t/h respectively. Because flat die pelletizer is a typical dry granulation equipment, you can spend less on drying and cooling. In addition, this machine has a favourable price of $ 1,000- $ 8,500. So it is an ideal choice for those who want to start a small scale pellets making at a low cost.

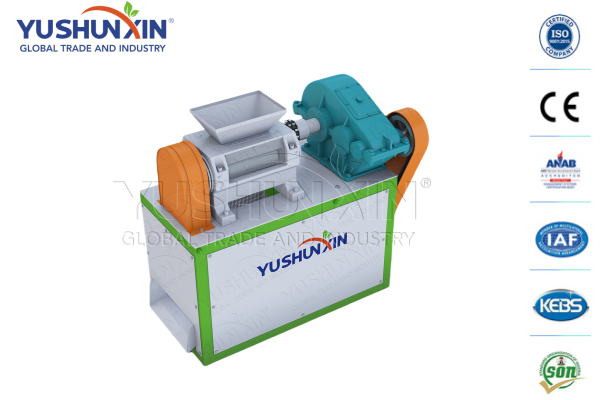

Double roller granulator with high granulation rate

Do you want to produce chemical material into pellets with high efficiency? Do you want to buy a fertilizer granulator with a low material returning rate? Here, we recommend you choose double roller pelletizer. Its granulation rate can reach 95%. Hence, there is only a small amount of materials needed to be returned to reprocess. And you can produce more qualified fertilizer pellets at the same time. For this, it has a favorable price. Only need $3,000-$12,000.

Is there a low investment project for fertilizer pellets making?

Of course. You can buy our basic granulation machine for organic and compound fertilizer making. It contains double roller granulator and disc pelletizer. And its smallest capacity model price is only $900-$3,000. Later, if you want to enlarge your organic or compound pellet manufacturing scale, you can buy more machines. Such as two or more disc pelletizers and double roller granulators. We prefer to recommend double roller granulation machine. Why? Because of dry granulation method employment, it don’t need to dry and cool finished fertilizer granules. Therefore, it has a lower cost.

Why YSX fertilizer granulator machines are cost-effective equipment?

In addition to meet customers different production requirements, fertilizer pellet making machine produced from YUSHUNXIN also have some significant advantages such as high working efficiency, long service life, low energy consumption and strong adaptability. Precisely because of these advantages, YSX fertilizer granulation machines are called cost-effective production equipment. Their advantages are as follows: