Coal Pellet Making Machine

Coal has a high content of carbon. In addition, it is one important raw material for making organic fertilizer pellets. Our factory has developed five main coal pellet making machines to produce coal pellets especially: new type organic fertilizer pellet making machine, rotary drum churning pelletizer, rotary drum granulation, pan granulator, and flat die pellet mill.

Below is more information about them for your reference. Hence, we’re going to talk about the reason you use our coal fertilizer pellet making machines, their models and granulation methods, and some tips for you to start a coal pellet making machines factory.

Environmental and Economic Benefits of Using Coal Pellet Granulating Equipment

In recent years of coal mining, there will be more and more powdery coal. Some coal blocks can also be powdery coal during far distance transportation. How to make use of these powdery coals has been a more and more obvious problem. However, our coal fertilizer pellet making machines can help you solve it. They can turn coal into pellets. Thus, you can know more details about how they work in the passage.

Besides, what benefits do you have by using our coal fertilizer pellet granulation machine? Or, why do you use a coal pellet granulation machine to make pellets? The answer is that you can have better environmental and economic benefits.

Coal is an important resource which can provide heat and power. As a result, its value is expensive. We can turn coal into coal fertilizer pellets by using our coal fertilizer pellet making machines. On the one hand, you can take use of coal’s economic value fully. On the other hand, coal fertilizer can provide high organic nutrients as a fertilizer. It has broad market demand. Therefore, you can have higher economic benefits by using our coal pellet making machines.

Coal accumulation not only occupies land resources, but also pollutes water and air quality under long time exposure. In this way, you turn coal into fertilizer pellets, which plays an important role in protecting the environment. The coal pellets can be used in the field, which plays a positive role in regulating soil compaction and revitalizing the land. Thus, you can have higher environmental benefits by using our coal pellet making machines.

Five Types of Coal Granules Making Machines for Commercial

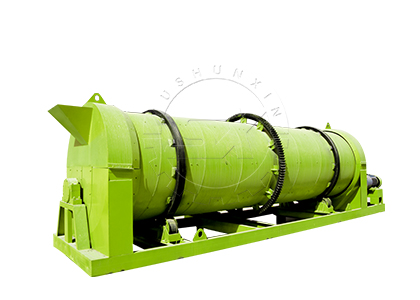

In summary, there are new type organic fertilizer pellet making machine, rotary drum churning pelletizer, rotary drum granulation, pan granulator, and flat die pellet mill for you to make coal fertilizer pellets. Here we’re going to know them one by one.

Besides, if you want to know about their designs and production capacity, you can contact our customer service for more details. Or if it is convenient for you, you can visit our factory in Xingyang, Henan. Welcome for your coming.

The new type organic fertilizer granulator equipment uses mechanical agitation force and aerodynamic force to achieve granulation cubsequently. There is no need to dry and mix the raw materials. Their production capacity is up to 1-8 tons per hour significantly.

Our Coal Pellet Granulating Machines Adopt Wet Granulation Method

To make coal into pellets, there are many granulation methods. However, wet granulation is one effective way to make coal fertilizer pellets. Among the five coal granular making machines, new type organic fertilizer pellet making machine, rotary drum churning pelletizer, rotary drum granulation and pan granulator all adopt the wet granulation. Take the new type organic fertilizer pellet making machine as an example, you will have a stronger sense for our coal pellets granulating equipment.

When a new type organic fertilizer granulator machinery works, you put adhesive into the powdery coal materials. Then the granules will coalesce by the function of the adhesive. Then under the function of stirring tooth, the pellets’ hardness will improve greatly. The pellets’ strength is up to 20-25N. The finished products by the new technology organic fertilizer plant granulation usually have the advantage of high quality, beautiful shape, strong wear resistance and high hardness.

Flat die granulator equipment adopts dry granulation primarily. It extrudes pellets from the die hole under the extrusion of the pressure roller. You can add various additives into the pellets’ processing. The materials are dry to put in and the dry products get out from the outlet. The natural temperature is up to 70-80 degrees, which can kill pathogenic microorganisms and parasites easily, and ensure organic matter content. They can keep for a long time in the water, which improves the materials’ utilization greatly.

Different with wet granulation, coal fertilizer pellets flat die granulator equipment can cut the cost of drying and cooling in the whole coal fines pelletizer production line. It is also beneficial for you by choosing our coal pellet flat die granulator equipment.

Cost.

After you have decided which type of coal pellets making machine is suitable for you, therefore, it’s time for you to think about the cost of building a coal pellets granulating equipment plant. If your budget is limited, you can choose our inexpensive coal fertilizer pellets making equipment. You can contact our customer service about the cost to have a further understanding.

Layout.

Though coal doesn’t have a bad smell like other manure fertilizers, the factories should also be built away from the living and working area of residents. This land’s rent is usually much cheaper than the land where people and businesses are dense. Thus, you can rent a large area for your scaled production at a cheap price.